Loading...

(a) Placement – General.

(1) An approved water meter shall be installed wherever City water is supplied and for all wells or other water sources that discharge into the City sewer system, in new construction, upon replacement or repair of a service line in an unmetered property, or on a retrofit basis the rules of the New York City Water Board (15 RCNY 42, Appendix A (Part VII, § 1)). The Department may require installation of additional meters as a condition for certain New York City Water Board rate or billing programs.

(2) (i) Each building must have one (1) meter on each service connection supplying the building set at the point of entry. However, the Department may issue a variance or approval allowing two (2) or more separate meters to serve residential and non-residential (or rate-eligible and ineligible) occupancies in the same building or lot to comply with a rate or billing program established by the New York City Water Board.

(ii) Properties with internal water mains must have a meter and backflow prevention devices in a vault or above-ground enclosure located at the property line at each connection to the city water system.

(iii) Unmetered properties with a lead or galvanized metal service pipe shall not be permitted to install a water meter except when accompanied with complete replacement of the lead or galvanized service line.

(3) Placement during building construction

(i) All water used in the construction of buildings 75 feet or six (6) or more stories in height shall be metered.

(ii) Prior to the commencement of actual building construction, a meter of proper size shall be installed on each tap or service pipe supplying the premises.

(iii) The meter shall be placed in an accessible location at a point to be designated by the Department.

(iv) The meter shall be close to the point of entry of the service pipe, and shall be enclosed in a vault or box of ample size and substantial construction which will provide adequate protection against damage or injury from frost or any other cause.

(v) Each meter shall remain in service throughout the entire period of building construction. If a different meter is to be used during operation of the completed building, a separate meter permit is required for that replacement.

(vi) Where the meter is inoperable, has not accurately measured the water supplied to the premises, or has not been maintained in good working order during the entire period of building operations, the charge for water consumed during building construction shall be established as provided by the New York City Water Board in accordance with the Water and Wastewater Rate Schedule.

(4) All water used in the construction of buildings less than six (6) stories in height shall either be metered or be supplied by a hydrant permitted in accordance with 15 RCNY § 20-08. If water used during construction is metered, the meter shall be placed as described in 15 RCNY § 20-05(a)(3). Permit applications for temporary water service during construction shall include the name and contact information for the Licensed Master Plumber or construction management company.

(5) Metering of fire service pipes and combined service pipes.

(i) Fire service connections: Fire service connections in premises supplied with City water must have an approved backflow prevention assembly. It can be either a double check detector or reduced pressure detector assemblies. Fire service connections of two-and-one-half (2 1/2) inches in diameter must be provided with valves, and fittings required for a three (3) inch service connection. Fire service connections supplying private hydrants must have fire service valves and fittings.

(ii) Service connections supplying both domestic and fire protection uses: DOB-approved combined services three inches (3") or larger in diameter must have either a single fire rate meter at the head of the service or, if separation between domestic and fire service piping branches occurs within sight of the head of the service, a meter approved for domestic service on the domestic service piping branch to domestic end uses and an approved backflow prevention assembly on the fire service piping branch serving fire protection system. Domestic services three inches (3") or larger in diameter with fire sprinkler heads take off must use a fire rate meter. Domestic services smaller than three inches (3") in diameter with fire sprinkler heads take off must have a meter approved by the Department. Pumped services to house tanks where the fire protection design is met by the volume of water in the house tank must use a turbine type or electronic type meter.

(iii) The use of water through meters or detector assemblies approved for fire sprinkler systems only is prohibited, except for fire suppression or the testing of the fire sprinkler system.

(iv) Inlet and outlet valves are not required for fire service meters or detector assemblies on combined service pipes, except for the building shut-off valve. A test tee must be provided for meter testing purposes on fire service meters. A test port shall not be placed on the bypass meter on a Detector Check Valve Assembly.

(b) Meter permits.

(1) No person shall set, reset, repair or disconnect a water meter used for Department billing purposes without having obtained a meter permit, except for sets, resets, repairs or disconnects done by the Department, its authorized agents or contractors. Applications for permits shall be made by a Licensed Master Plumber duly authorized by the customer; provided, however, that applications for permits to reset, repair or disconnect a water meter may be made by a meter repair company authorized by the Department.

(2) Within ten (10) business days following the completion of any work for which a meter permit has been issued, the permit, carrying: (i) a certification of the date of completion of the work, (ii) the final reading from the old meter (for replacements or repairs) and (iii) the meter manufacturer's accuracy test document for the new meter shall be returned to the Department. The Department may, in its discretion, grant an extension of the 10-day timeframe in which the permit must be returned, upon a submission by the permittee showing that there is a practical difficulty in complying with the 10-day timeframe and providing a timetable for return of the permit. A permit shall expire after 365 days for new construction work and after 30 days for meter replacements or first-time meter installations in existing buildings. If the work is to be performed after that time, the Licensed Master Plumber must apply for a permit extension before the original permit expires. [

(3) After acceptance by the Department of the meter work, indicated by installation of a seal, or after one year from the return of a completed permit with access to the property available for the Department to inspect the work, whichever comes first, such meters will be owned, maintained, repaired and read by the Department. If access to the property is not made available to the Department, a denial of access notice shall be issued to the property owner.

(4) Design approval for water meter installations shall be obtained from the Department's Bureau of Customer Services as required by Sections 603.3 and 603.5 of the New York City Plumbing Code. Approval of a backflow prevention design as required by 15 RCNY § 20-04 shall not constitute approval of the meter installation.

(c) Work on small meters.

(1) No person other than authorized Department personnel, its contractors or permit holders shall set, reset, repair or disconnect a water meter on service pipes of less than one and one-half (1 1/2) inch diameter.

(2) Meter testing or repair companies. A meter testing or repair company authorized by the Department may obtain permits to perform testing or repairs of water meters by demonstrating that it has detailed written testing or repair procedures that have been approved by the Department and a detailed written training program.

(i) A permit applicant's written procedures and written training programs must include, at a minimum:

(a) Meter accuracy testing and reporting of results, as specified in the most recent version of American Water Works Association (AWWA) Manual M6;

(b) Written procedures that reflect a detailed understanding of the application of different meter technologies to different buildings and plumbing systems; and

(c) Detailed written instructions for performing meter repairs, meter accuracy tests, and other inspection procedures.

(ii) A permittee shall annually submit to the Department documentary proof that any portable or bench test equipment has been tested and calibrated by a National Institutes of Standards and Technology (NIST)-certified lab or company, to confirm accurate operation of the testing equipment.

(iii) The Department reserves the right to withdraw its authorization if it finds that the meter testing or repair company is not abiding by the standards set forth in the work procedures approved by the Department.

(d) Approved water meters. Meters shall meet the following requirements:

(1) All water meters used for billing purposes must comply with applicable specifications of the most recent AWWA Standards for Water Meters, and/or be specifically tested and approved by the Department as to their accuracy, performance and construction. The Department shall maintain and regularly update a list of approved water meters, detector assemblies, pit meter equipment, meter attachments and meter-associated equipment.

(2) The following information shall be on all meters used for billing purposes:

(i) Size and model of meter;

(ii) Trade or brand name of meter; and,

(iii) Direction of flow.

(3) The serial number of the meter shall be imprinted on the case, meter body, or flange in a permanent manner and all meter serial numbers shall be unique for the manufacturer.

(4) All meters used for billing purposes shall read in cubic feet. Meters sized five-eighths (5/8), three-fourths (3/4), or one (1) inch shall have a remote read resolution of no more than one (1) cubic foot. Meters sized one-and-a-half (1 1/2) or two (2) inches shall have a remote read resolution of no more than ten (10) cubic feet. Meters three (3) inches and larger shall have a remote read resolution of no more than one hundred (100) cubic feet. Meter registers shall have an error rate, including any missed reads, of no more than 0.000150% on an annualized basis.

(5) All meters used for billing purposes shall be compatible with the Department's automatic meter reading system. Such compatibility shall be certified by the Department.

(6) Positive displacement meters 5/8" through 1 1/2" must conform to the most recent version of AWWA Standard C700. 2" positive displacement meters are not approved for use after January 1, 2021.

(7) All meters must have a main case composed of an alloy which does not have a lead content that exceeds current NSF/ANSI Standard 61/372 limits. Upon request by DEP the meter manufacturer must submit all documentation associated with its product's compliance with NSF 61/372.

(8) Meter manufacturers shall notify the Department at least thirty (30) days after any changes in design, serial numbering, or other matter that might affect the use of the water meter or billing processes.

(9) Any main meter case made of plastic or other non-metallic material shall be commercially recyclable or shall be recycled by the manufacturer or its agent. Any main meter case made of plastic shall have metallic threaded connections unless specifically approved by the Department for composite or plastic threads.

(10) Any meter that requires a battery other than for temporary backup power for proper operation shall be provided with a manufacturer's warranty at least equal to the claimed life of the battery, or ten years for meters one-and-a-half (1 1/2) inch and larger or 15 years for meters smaller than one-and-a-half (1 1/2) inch, whichever is longer.

(11) The manufacturer must provide each meter supplied to a distributor after January 1, 2020 with a removable barcode tag and sticker meeting the Department's Enhanced Barcode Specifications available on the DEP website.

(12) All meters installed in any pit or vault, or installed in the basement of a building lying in a designated floodplain, shall have factory, waterproof wiring connections and shall be rated by the manufacturer for submersion in water.

(e) Compound, turbine, electromagnetic, and single-jet meters.

(1) Meter Applications.

(i) Effective May 1, 2014, compound or dual-register meters may no longer be approved for use in new or replacement installations.

(ii) Horizontal turbine meters shall be used wherever water is supplied to roof tanks by pumps or to buildings by other pumped, constant flow application, and may be used in buildings with booster pumps or pressurized supply systems as long as such systems' minimum non-zero flow rate is greater than the low-flow end of the 98.5% AWWA operating range for the specific meter model.

(iii) Electromagnetic meters may be used in place of turbine meters where the flow rating of the pump does not exceed the high end of the published normal operating flow rate range for the electromagnetic meter.

(iv) Single-jet, electromagnetic, or other meters designed for variable flow rates must be used on services one-and-a-half (1 1/2) inch and larger in diameter and operating on street pressure, and may be used in buildings with booster pumps or pressurized system applications.

(v) Single-jet meters must be installed on a level horizontal plane +/- 10 degrees. Turbine, electromagnetic, and other meter types may be installed on an incline or vertical plane if a horizontal installation is not possible and the configuration is supported by the meter manufacturer's specifications. The meter register must always face outward for reading. Electromagnetic meters must be grounded according to the manufacturer's requirements and must not be located in the same room as a significant source of an electromagnetic field such as a motor generator.

(2) An approved flat plate or "Z" meter strainer shall be installed on all new or replacement turbine meter installations, unless the turbine meter is manufactured with an internal strainer. Such a strainer is not required for electromagnetic or single-jet meters, but its use is permitted.

(3) [Repealed.]

(4) [Repealed.]

(f) Used or repaired meters. No used or repaired meter shall be installed to cover a service pipe at the same or a different location unless it has been repaired, tested for accuracy, found to conform to AWWA new meter accuracy standards and has been approved by the Department.

(g) Sizing.

(1) A meter shall be restricted to a size and type that will insure accurate registration on the basis of the water requirements of the premises, or portion of the premises, to be metered. For residential premises, the permit applicant shall perform a fixture count and develop a peak flow estimate using Appendix Tables #1 and #2. The meter shall be sized according to Appendix Table #8. For non-residential premises, the flow rate shall be based on the analysis of a Licensed Professional Engineer or Registered Architect. The meter shall be sized according to that flow rate and Appendix Table #8.

(2) A meter shall not be larger than the service pipe supplying the meter, the piping in the meter setting, or the water distribution piping in the building, unless specifically approved in writing by the Department or as noted in 15 RCNY § 20-05(a)(5) for two-and-one-half (2 1/2) inch fire services or combined services. If two meters both cover the calculated peak flow rate, the smaller of the two meters shall be used unless approved in writing by the Department. Unless a fixture count and flow analysis, as described in 15 RCNY § 20-05(g)(1), has been approved by the Department, a one- or two-family home with gravity-flush water closets shall not have a meter on a domestic service without fire sprinklers larger than three-quarters (3/4)) inch and three-, four-, five- and six-family homes shall not have a meter on a domestic service larger than one (1) inch. Exceptions to these requirements, and the use of Appendix Table #8 for meter sizing, will be considered by the Department only when a building's plumbing system uses only street water pressure and documented incoming water pressure is less than 35 psi for buildings four (4) through six (6) stories high, or less than 30 psi for buildings less than four (4) stories in height.

(3) The minimum size meter for new installations and replacements shall be five-eighths (5/8) inch.

(4) The appropriate low-flow range for compound meters varies with the manufacturer. The ranges of sizes in Appendix Table #8 refer to the high-flow side. The Department may require that a permit applicant provide a basis for using a compound meter instead of another type of meter. That justification must outweigh the higher maintenance and other operating costs to the Department of the compound meter.

(h) Tests. The permit applicant shall submit the manufacturer's meter accuracy test results to the Department at the time of permit application. The Department retains the right, in specific instances, to require that a new, used or repaired meter be sent to a designated Department facility for testing at the owner's expense.

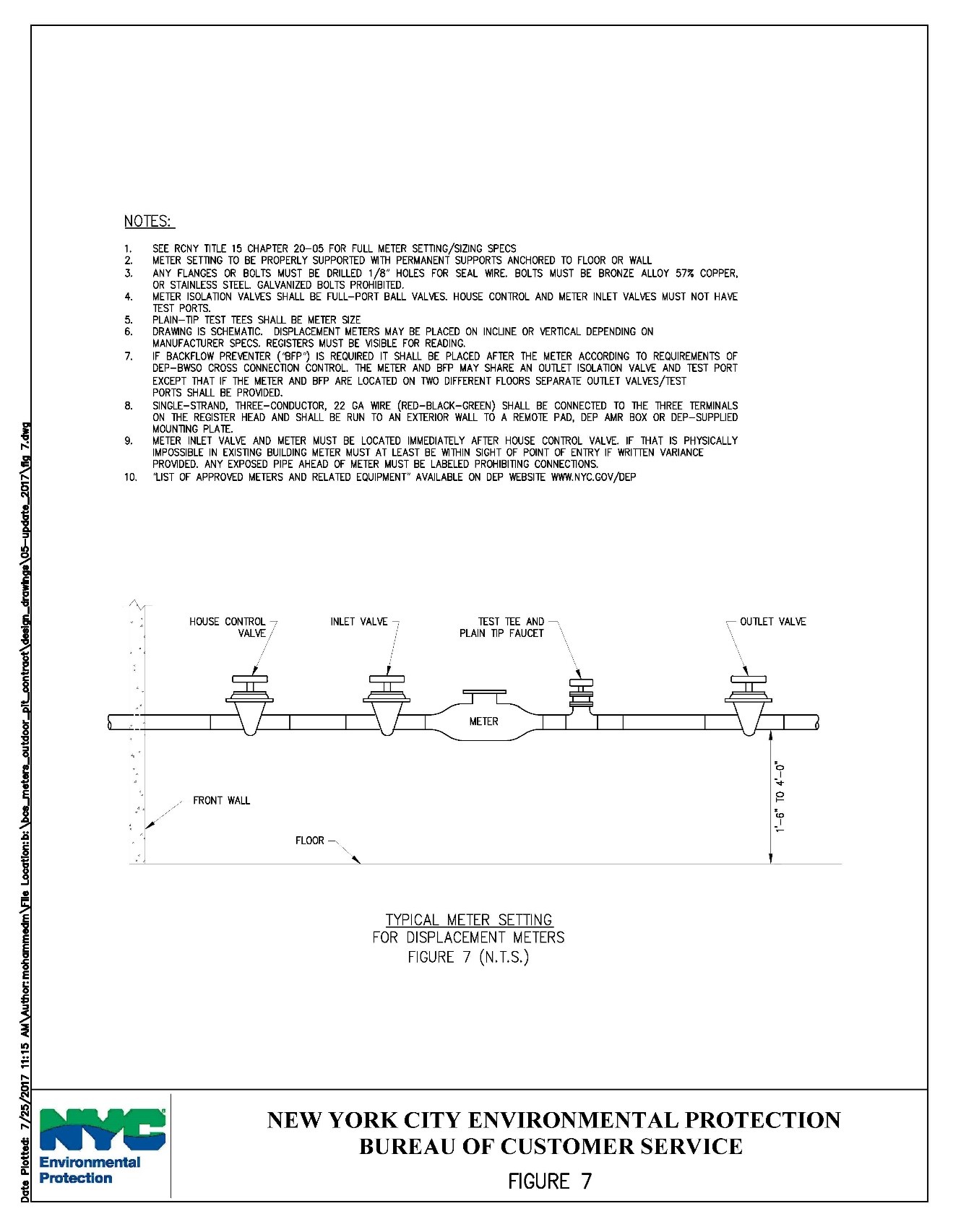

(i) Settings. Notwithstanding any other provisions to the contrary, all meters shall be set or reset according to the following requirements:

(1) Meters shall be set as near as possible to the point of entry of the service pipe through the building or vault wall and shall be placed so that they may be easily inspected, maintained and replaced. Evaporative cooling tower meters or other meters used to calculate a wastewater allowance when located downstream of a billing meter shall be placed as close to the end use as practical. A property owner shall not erect or maintain any physical barrier that prevents access to, or repair or replacement of, the water meter.

(i) Displacement meters shall not be set beyond three (3) feet of the entry point without written approval from the Department.

(ii) Turbine and compound meters shall be set with straight sections of pipe as provided in Appendix Figures #7, #7A, #9, #9A, #10 and #10A. If pipe lengths cannot conform to those indicated in Appendix Figures #7, #7A, #9, #9A, #10 and #10A, a meter technology shall be used which does not require minimum straight pipe lengths. The Department shall identify such meter technologies in its list of approved meters. An approved meter strainer is required unless one is included in the meter design or in the case of single-jet or electromagnetic meters, is not required by the meter manufacturer.

(2) No fittings capable of a branch connection are permitted in the section of connection upstream of the meter or meter setter with the exception of an approved strainer. The strainer must be located immediately before the inlet side of the meter. The service connection between the point of entry and the meter setting must be kept visible. No fittings, devices, or equipment are permitted in the section of connection upstream or downstream of the meter that interferes with the required laminar flow through the meter, except as otherwise approved by the Department, Bureau of Customer Services.

(3) If conditions exist that prevent the setting of a meter in accordance with the above requirements, the meter may be set outside the building in a meter pit, vault or above-ground meter box (See 15 RCNY § 20-05(k)).

(4) Meter settings must have an inlet valve immediately upstream of the meter and any strainer, and an outlet valve downstream of the meter. For meters two (2) inches in size or smaller, the valves must be full-port ball valves. For meters larger than two (2) inches in size, the valves must be rising stem, resilient seated, and epoxy-coated gate valves. If a backflow prevention device is located after the meter setting and both the backflow prevention device and meter setting are located on the same floor of a building, then an outlet valve serving the meter setting may be placed immediately after the device. If a backflow prevention assembly is located after the meter setting, then an outlet valve shall be placed immediately after the assembly and the meter test tee.

(i) Except for meters two (2) inches or smaller where space constraints prevent any approved meter technology from being installed with an inlet valve, or as noted in 15 RCNY § 20-05(a)(5), a house control valve must not be used in lieu of a meter inlet valve.

(ii) On a dedicated fire service line, an approved backflow prevention assembly (DCDA or RPDA with by-pass meter) in conjunction with the building control valve are required. Additional valves are optional.

(iii) A plain tip test tee must be provided for meters 3/4" or 1" in diameter before the meter outlet valve or incorporated into the design of the meter outlet valve. For meters 1-1/2 inches in diameter, the test tee must be the same size as the meter. For meters 2 inches or larger than two (2) inches in diameter, the test tee must be two (2) inches. An exception shall be provided for installations using an outlet valve that incorporates an one-and-a-half (1 1/2) inch rather than two (2) inch test tee into the design of its two (2) inch outlet valve. Factory-fabricated setters five-eights (5/8) inch through two (2) inches must have test ports as described in paragraph 6 of this subdivision. Test port plugs on meter bodies must be drilled for seal wire. Test tees shall not be used as water supply connections. Where a meter is placed in a pit alongside a sewer trap, the meter test tee must be located outside of the pit in an accessible location.

(5) Connections must be made by coupling, union, flange union or approved compression fittings and bored for sealing with holes not less than three thirty-seconds (3/32) of an inch in diameter. Compression fittings are permitted for three quarter (3/4) inch through two (2) inch meters only. Unions, couplings or compression fittings that permit removal of the meter and/or setter without breaking the seal wire are prohibited. Grooved end mechanical pipe joining systems are not permitted between the meter inlet valve and the outlet side of the meter. If used on the service side of the house valve, such systems must be drilled for seal wire. In all other circumstances, pipe joining specifications must conform to the New York City Plumbing Code. All water meter settings of two (2) inches and smaller sizes must utilize valves and fittings constructed of bronze with a lead content that must not exceed current NSF/ANSI Standard 61 limits. Bolts, studs, nuts, screws and other external fastening devices used from the house valve through the meter outlet valve must be made of a bronze alloy or stainless steel conforming to AWWA standards, and must be designed for easy removal following lengthy service. Above-ground, indoor service connection, including the meter setting and any backflow prevention device, must comply with standards for water distribution pipe contained in the New York City Plumbing Code Section 604.

(6) Meter setters & resetters. Meter setters and resetters five-eighths inch (5/8) through two inch (2) shall conform to the following:

(i) Seamless copper tubing having a type K wall thickness in accordance with ASTM B 88 specifications shall be used for all prefabricated water meter setters. All bronze parts shall be an alloy with a lead content that shall not exceed 0.250%.

(ii) The internal waterway shall be equal to the meter size to be installed, i.e. one (1) inch meter = one (1) inch internal diameter.

(iii) The end of the copper tubing at the meter coupling for three quarter (3/4) inch and one (1) inch meters shall be spun and/or formed to produce a strong positive bearing surface on the full face of the gasket and meter spud.

(iv) Copper tubing arms shall be affixed to the setter body using leadless solder at the cup joint.

(v) All setters, valves and compression adapters shall be designed to ensure positive electrical bonding continuity with, or without, the meter being set, via an approved external method which can be confirmed visually.

(vi) All setters shall be designed to avoid any significant head loss.

(vii) An approved test port located between the meter and the outlet control valve shall be included in the design of all setters. The test port shall be capable of delivering flows from at least one quarter (1/4) to two (2) gpm, but no more than four (4) gpm.

(7) Above-ground, indoor service pipe, including the meter setting and any backflow prevention device shall be Type K or Type L copper, if copper is acceptable for that size service pipe.

(8) Valves. All new displacement type water meter settings must utilize full port ball valves for the inlet and outlet control of the meter. All valves must be furnished with handles for the manual operation of the valves without the need of a wrench. Other meter types must be installed with full port ball valves (through two (2) inch only) or gate type OS&Y valves for meters larger than two (2) inches.

(9) Meters shall be set as shown in Figures #7, #7A, #9, #9A, #10 and #10A.

(10) All meter settings shall contain a test tee or test valve downstream of the meter and before the outlet valve. The test tee/valve can be incorporated as part of the outlet valve design.

(11) Any connection to a test tee assembly or to any point ahead of a meter used for billing purposes is strictly forbidden.

(12) Electrical continuity. All settings shall be designed to ensure positive electrical continuity with, or without, the meter being set, via bronze grounding clamps with stainless steel screws and electrical bonding cables (#6 THHN-THWN) which can be confirmed visually, unless a pre-fabricated setter designed for electrical continuity is used or the water service is known not to be used as an electrical ground.

(13) Meters settings shall be provided with holes for running seal wire to be installed by the Department. The meter installation shall include either one-eighth (1/8) inch holes drilled in a bolt on each end flange, or an one-eighth (1/8) inch hole drilled in one or both flanges.

(j) By-pass.

(1) Unmetered by-passes around meters are prohibited. Properties that wish to avoid lengthy interruptions of water supply may install a metered by-pass or a set of two parallel meters, under permit and at their expense.

(2) If a by-pass is permitted by the Department, the installation shall conform to Appendix Figure #10 or #10A. The by-pass shall be configured so that the top case and interior meter can be removed for repairs or replacement.

(3) Properties that wish to avoid lengthy shutdowns related to replacement of large meters may install paired meters that can supply the building through one or the other meter on a service connection.

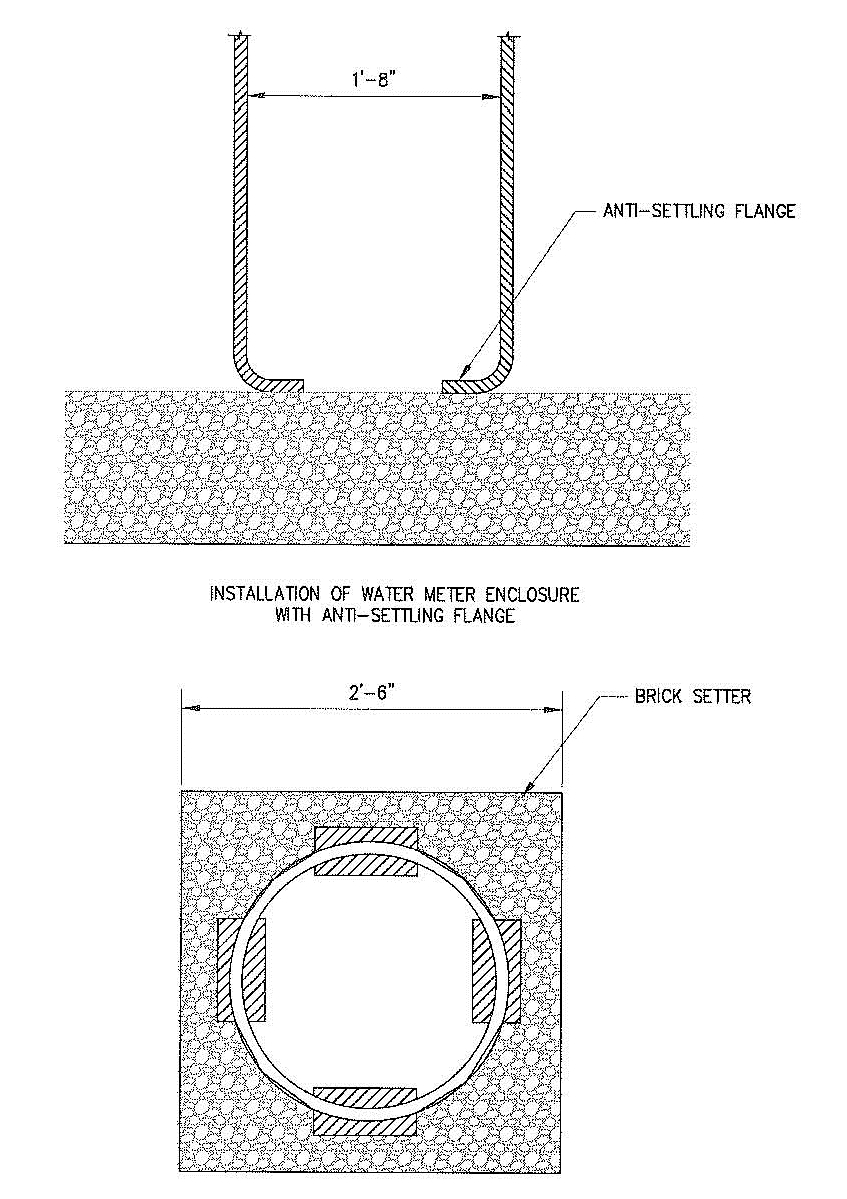

(k) Meter pit/meter box requirements. Meter pits shall be constructed in accordance with the following requirements:

(1) All meter electrical connections shall be factory sealed to be water proof.

(2) The Department shall maintain detailed specifications for three quarter (3/4) inch and one (1) inch pit meter installations and equipment including setters, enclosures and covers.

(3) Meter pits for meters less than 3".

(i) For meters less than three (3) inches, the enclosure shall be frost-proof and shall follow one of these alternate requirements:

(a) Thermoplastic polyvinyl chloride (PVC) conforming to ANSI/ASTM D 1785, Type I, Grade 1, seamless, extruded pipe with white interior. The enclosure shall be as uniform as commercially practicable in color, opacity, density and other physical properties. Thickness shall be at least one-half (1/2) inch.

(b) Polyethylene (PE) enclosures shall be constructed in accordance with the ANSI/ASTM D 2104 latest revision. The PE shall be of medium density. Polyethylene shall conform to all applicable sections of the latest edition of ASTM D 1598, and ASTM D 1599. Thickness shall be at least one-half (1/2) of an inch.

(c) A composite of polyester resin, fiberglass and calcium carbonate. The composite material shall consist of non-aggregate base materials using the bulk molded compound process or the thick molded compound process. The thickness shall be at least one-half (1/2) inch.

(ii) Covers and lids shall be constructed in accordance with the following requirements:

(a) Covers shall be of polymer concrete, heavy duty plastic, or other composite materials that allow transmission of an AMR signal and meet load requirements set by the department. The department shall publish a list of approved products and materials in its list of approved meters and equipment.

(b) Lids shall have a lifter worm lock with a standard waterworks pentagon nut constructed of bronze.

(c) Extra heavy lids and covers shall be used for driveway and sidewalk applications.

(d) For three quarter (3/4) inch and one (1) inch meter sets, covers shall fit on twenty (20) inch nominal I.D. meter vaults. Covers shall have thirteen and one-half (13 1/2) inch to fifteen (15) inch openings and lid sizes.

(e) For one and one-half (1 1/2) inch and two (2) inch meter sets, covers shall fit on thirty-six (36) inch nominal I.D. meter vaults. Covers shall have eighteen (18) inch to fifteen (15) inch openings and lid sizes.

(4) Meter vaults for meters 3" and larger. For meters three (3) inches in size and larger, a meter vault shall be constructed as follows (See Appendix Figures #11 through #17 for typical meter pit and vault installation details):

(a) Waterproof and frost proof and of sufficient size to permit easy access to all portions of the meter and connections with at least one (1) foot clearance on each side of meter.

(b) In conformance with any requirements of the U.S. Occupational Safety and Health Administration.

(c) Pits less than four (4) feet in depth shall not be less than two feet, six inches (2'6") wide and three feet, six inches (3'6") long. Pits less than four (4) feet in depth shall be provided with a hinged cover not to exceed forty (40) pounds in weight, with suitable handle and so constructed as to permit the uncovering of entire pit, or a circular cover as described above in (ii) provided that there is sufficient clearance to remove and replace the meter.

(d) Pits four (4) feet or more in depth shall be provided with an access opening of at least two feet, six inches (2'6") square or at least thirty (30) inches in diameter, but of sufficient size to remove and replace the meter. If the access opening is square, the cover of such opening shall be hinged and shall be provided with a suitable handle. Doors exceeding forty (40) pounds in weight shall be counter balanced. Approved composite lids or covers for vaults are available from the Department.

(e) Pits three (3) feet or more in depth shall be provided with permanent steps or a metal ladder.

(f) Pits containing sewer traps shall be provided with an air vent.

(5) Meter boxes (above-ground enclosure).

(i) The enclosure must be capable of housing the water meter with all required valves, strainer and above-ground accessories. It must have easy access for testing and maintenance including at least one (1) foot, clearance around the meter, piping and valves. The boxes must have lockable access doors or lids to prevent theft or vandalism. The enclosure must be anchored to a concrete base of eight (8) inches minimum for meters one and one-half (1 1/2) inches or larger, and four (4) inches for meters less than one and one-half (1 1/2) inches. The enclosure must have an approved remote meter reading receptacle mounted on the exterior.

(ii) The enclosure shall be a minimum of:

(a) Eighteen (18) gauge reinforced aluminum, or;

(b) Extra heavy duty fiberglass reinforced polyester with high-gloss gelcoat finish, or;

(c) Twelve (12) gauge steel finished with three coats of baked enamel.

(iii) The enclosure shall be insulated with a material in addition to the enclosure itself which has a thermal resistance ("R-value") of at least 8.0.

(iv) The enclosure shall have a thermostatically-controlled heat source mounted to the interior wall for freeze protection down to -10°F.

(l) Metering condominium and homeowners' association developments.

(1) An individual water meter to be read by the Department shall be installed for each separately-owned dwelling unit in all new condominium and homeowners' associations structures of three (3) stories or less when each such unit is supplied with hot water and space heat by its own separate domestic hot water heater and space heating system, and not by a common water heater or space heater. If fire protection sprinklers are present they shall be supplied by a separate dedicated service pipe. Any hose bib or irrigation supply shall be connected to one of the unit's metered branches. Such individual water meters shall be located in a common location immediately after the point of entry in each structure, with each meter clearly labeled as to the unit it supplies. MTUs shall be mounted on the exterior walls of the building. New and existing condominiums and homeowners' associations structures of six (6) stories or fewer with in-unit hot water heaters and space heating systems may apply to install individual water meters at their cost and in the same manner and governed by the same conditions as meters for new condominiums and homeowners' associations structures of three (3) stories or fewer, unless the work is physically impractical or the owners do not agree to individual water meters or required MTU placement. Such existing structures requesting individual water meters shall not be in arrears with their water or sewer accounts or payment agreements at the time of application to the Department. The Department shall set specific written requirements for such applications. For all cases, if there are building common end uses, such as but not limited to irrigation and heating boilers, then individual water meters in the name of the condominium or homeowners' association shall be installed for those uses. Properties served by internal water mains shall be metered as specified in 15 RCNY § 20-05(a)(ii).

(2) Condominiums and homeowners' associations that cannot be individually metered as described in 15 RCNY § 20-05(l)(1) shall have a meter at the point of entry of the water service for the building or buildings, except that those properties served by internal water mains shall be metered as specified in 15 RCNY § 20-05(a)(ii).

(3) Each individual unit/meter shall have its own account under the "75XX" joint condominium lot.

(m) Removal.

(3) If a meter is moved, a permit shall be obtained to report the new location. Relocation of a meter from an outdoor pit to an indoor location shall include filling the pit with clean sand and restoring the surface in kind.

(n) Seals. A seal placed by the Department for the protection of any meter, valve, fitting or other water connection shall not be tampered with or defaced. The seal shall not be broken except after securing a permit from the Department. Breaking the seal without such a permit shall be a violation, except for emergency repairs as described in 15 RCNY § 20-01(f). The Department may also remove the meter for testing and resetting or replacement. The customer shall be responsible for safeguarding and protecting the seal and the meter. Application of a seal on a new or replacement meter shall denote approval by the Department.

(o) Meter shut-off. Where water is obtained through more than one (1) meter, and where tests indicate accurate registration is not being obtained by reason of the divided delivery of water, the Department may, at its discretion, shut off and seal the meter(s) to ensure accuracy of registration.

(p) Protection of meters and settings.

(1) The property owner shall protect the meter, setting, AMR transmitter, wiring and remote against physical damage, freezing conditions and abuse. The property owner shall be responsible for any break or disconnection of wire within the building. The property owner is responsible for preventing physical deterioration or other conditions of the service pipe which may damage a meter or prevent its maintenance or replacement. In such cases the owner shall be responsible for repairing or replacing equipment, service piping or any other physical barriers, including asbestos insulation, needed to allow maintenance, proper operation or replacement of the meter.

(2) The property owner is prohibited from relocating the remote receptacle or AMR transmitter except upon securing a permit from the Department.

(3) The property owner's installation of branch meters or submeters for the owner's use shall not interfere with the City's meter setting.

(q) Encoding registers. When used, all encoder-type remote registration systems must comply with all applicable requirements of AWWA Standard C707 and the following requirements:

(1) The register must encode at least the six (6) most significant digits which will be read from the remote receptacle.

(2) The unit must employ a leak detection indicator, gpm display or a test sweep hand on the face of the meter register.

(3) Registers must read in cubic feet.

(4) The assembly must have a tamper resistant locking device as well as a provision for seal wire, or other method approved by the Department.

(5) The data stream must be, or be convertible to, ASCII format, and is to be capable of interfacing directly to a Department-approved automatic meter reading device.

(6) All encoder registration systems must be capable of transmitting the data for a minimum distance of three hundred (300) feet utilizing solid twenty-two (22) gauge minimum non-shielded copper cable between the register and the remote receptacle or interface device.

(7) All encoding registers must be subject to the approval of the Department.

(8) The register must be capable of being read through a remote receptacle, and /or an automatic meter reading system.

(9) All registers must be installed with wire to a AMR transmitter with all three wires properly connected at the register head.

(r) Remote receptacles and AMR transmitters ("MTU").

(1) Temporary use of remote receptacles or pads. The licensed plumber performing the meter installation or replacement shall run wire from the meter register to an exterior wall. If the licensed plumber installs a meter manufacturer's remote receptacle or pad for temporary use, installation shall be in a location consistent with the specifications in paragraph 2 for placement of an MTU until the Department replaces the remote receptacle or pad with an MTU. Any splices of wire running from the meter register to the remote receptacle or pad must be sealed with gel caps. All three of the wire connections at the meter register must be connected to wires running to the remote receptacle or pad, even if only two wires are connected at the remote receptacle or pad. The third wire shall be tucked behind the remote pad.

(2) Placement of MTU or temporary remote receptacle. Placement of the MTU shall comply with the following guidelines:

(i) Location. The MTU shall be located on the front or side exterior of the building, unless such building and an immediately adjacent building have aluminum siding or other signal reflective material in which case the MTU shall be located on the front exterior only. The MTU must be located above ground level, and must not be placed behind permanently-sited large metal objects. All wire splices shall be sealed with gel caps. For apartment or office buildings with glass, marble or other similar facades, a smaller optional remote antenna MTU is available from the Department, or the MTU may be located inside a building if transmissions can be received by the AMR system. The location of the MTU must be indicated in the meter permit as returned to the Department.

For all underground meter installations, the remote pad shall be mounted in the meter pit lid or some support or structure immediately adjacent to the pit, to allow meter readings without opening the lid.

(ii) Height. The receptacle shall be set at forty-two (42) inches above ground, but may be set between twelve (12) and sixty (60) inches if circumstances preclude a better height. Receptacles may be installed beyond these limits only when approved in writing by the Department.

(3) AMR transmitter. AMR radio transmitters (MTUs) for domestic meters shall be mounted on the exterior surface of an exterior building wall above ground level, unless otherwise specified by the Department. AMR radio transmitters for evaporative cooling tower makeup water meters or other meters located on the upper floors of a building shall be mounted on the exterior of the building wall, at a roof parapet or other location to permit effective transmission of the radio signal. Meters placed in outdoor pits or vaults shall have MTUs mounted on the underside of approved composite plastic pit lids or covers available from the Department.

(s) Meter attachments.

(1) No customer shall attach any device to the water meter unless such device has been submitted to, and approved by, the Department.

(2) No device submitted for approval shall interfere with or affect the operation, inspection or reading of the meter in any way.

(3) Any device approved is solely the responsibility of the property owner unless it is installed by the Department. The Department is not liable for any maintenance or replacement of any approved attachments to the meter, and shall not perform any additional steps to salvage the devices should the meter require replacement. Meter attachments are not recognized as a source of data for billing purposes. A technical representative of a meter attachment manufacturer may be a permit holder for Meter Attachment permits only.

(4) The Department shall publish a list of approved meter attachments as part of its list of Approved Meters.

(t) Ownership of water meters. All water meters used for billing purposes are the property of the Department. At the time of replacement or removal, one or more photographs of the meter must be provided to the Department that must include the serial number of the meter and the final meter read. The Department may, upon written request prior to the removal or replacement of a meter, require the return of a meter to the Department for testing or other purposes. Failure to 1) provide photographs of a meter; and 2) return a meter to the Department when requested by the Department, at the time of replacement or removal is a violation of this rule.

(Amended City Record 7/26/2021, eff. 8/25/2021; amended City Record 1/18/2023, eff. 2/17/2023) [

(a) General rules.

(1) Air conditioning and refrigeration.

(i) Each direct water connection to a refrigeration or air conditioning unit using City water for cooling purposes shall be equipped with a check valve set not more than two (2) feet from the unit.

(ii) Each unit containing more than twenty (20) pounds of refrigerant shall be provided with a relief valve installed between the check valve and the unit. The relief valve shall be set at five (5) pounds above the maximum water pressure at the point of installation.

(iii) All water-cooled air conditioning or refrigeration systems shall be connected to a metered supply.

(iv) Water conserving devices shall be designed and operated in accordance with American Society for Heating, Refrigeration and Air Conditioning (ASHRAE) standards that consumes City water for make-up purposes at no more than two (2) percent of the total flow of water through the system. An additional two (2) percent shall be allowed for the purpose of bleeding and wash down.

(v) Where the City water is piped to a water conserving device, the piping supplying such water shall discharge at least two (2) inches above the over-flow rim of the pan.

(vi) Condensate from steam used directly or indirectly to produce the cooling effect in air conditioning or refrigeration systems shall be collected and used as part of the make-up water to the water conserving device or shall be put to some other beneficial use which displaces potable water.

(2) Refrigeration.

(i) All refrigeration systems in excess of six (6) tons of rated capacity using City water and installed before January 1, 2011 must be equipped with approved water conserving devices. Once-through, water-cooled refrigeration systems are prohibited in new construction effective January 1, 2011, in accordance with § 428.1.1 of the New York City Plumbing Code.

(ii) All refrigeration systems of six (6) tons of rated capacity or less using City water without an approved water conserving device shall be equipped with an automatic water regulating device on each individual unit.

(3) Air Conditioning.

(i) All air conditioning systems in excess of two (2) tons of rated capacity using City water and installed before January 1, 2011 must be equipped with an approved water conserving device. Once-through, water-cooled air conditioning equipment is prohibited in new construction effective January 1, 2011, in accordance with § 428.1.1 of the New York City Plumbing Code.

(ii) All air conditioning systems of two (2) tons of rated capacity or less using City water without an approved water conserving device shall be equipped with an automatic water regulating device on each individual unit.

(b) Hours of use of air conditioning systems.

(1) Hours of use of air conditioning systems may be limited by the Department from time to time as water supply conditions so warrant.

(2) Lists of "permissible hourly operation" will be on file in the Department and may be obtained upon request.

(3) The hours during which air conditioning using City water is allowed shall be posted prominently in each building and establishment using such air conditioning.

(c) Variances. The Department will receive and review requests for variances from this section due to demonstrated peculiar individual situations.

(a) General regulations. All corporation stops (taps), wet connections (including internal water main), meters, service connection installations, repairs, plugs and relays are subject to inspection by the Department. A Licensed Master Plumber must certify that all work was performed in accordance with these Rules and all other applicable rules.

(1) Corporation stops (taps/wet connections) and service connections supplying water to the fire suppression systems: sprinkler and/or standpipe and fire hydrants (private).

(2) Corporation stops (taps/wet connections) and service connections supplying combined water systems or domestic water systems to which fire systems are connected.

(3) Water service terminations (plug only).

(4) Destruction of any tap or wet connection which requires an excavation separate from the one required for the new tap or wet connection.

(5) Installed new wet connections and corresponding service connections.

(6) Relay or repair of sprinkler, fire, standpipe and domestic service connections to which fire sprinkler heads are connected.

(c) Inspection waiver. For domestic water service connection installations where inspections are mandatory, as described in 15 RCNY § 20-07(b), the Department in its discretion may waive such inspections. If the Department waives an inspection, the Licensed Master Plumber must submit the tap location with certification that all work was performed in accordance with these Rules and all other applicable rules.

(d) Fee for inspections. An upfront fee must be paid for each inspection in accordance with the Water and Wastewater Rate Schedule of the New York City Water Board.

(e) Inside flow test.

(1) A Licensed Master Plumber may submit a written request for permission to conduct an Inside Flow Test in lieu of a mandatory inspection. Such requests may be granted, at the discretion of the Department, but only upon demonstration of substantial hardship.

(2) Where a request for an Inside Flow Test is denied, the Licensed Master Plumber shall re-excavate and make the work available for an inspection.

(3) When performing an Inside Flow Test, the Licensed Master Plumber shall provide all necessary tools, gauges, hoses, etc.

(4) An Inside Flow Test shall be conducted, in the presence of a Department inspector, as follows:

(i) The Licensed Master Plumber installs a pressure gauge on the water service pipe near the entry to the premises.

(ii) The Department inspector records the static pressure.

(iii) The Licensed Master Plumber runs a large quantity of water to waste within the premises.

(iv) The Department inspector records the dynamic (with flow) pressure. Pressure readings with a measurable difference between the static pressure and the dynamic (with flow) pressure shall be acceptable.

(f) Permit at work site. The Licensed Master Plumber must display the permit at the work site except for emergencies.

(g) Inspection hours. The Department will conduct inspections Monday through Friday (except holidays) between the hours of 7:30 a.m. and 5:00 p.m., except upon a demonstration of substantial hardship.

(h) Backfilling before 2:00 p.m. Backfilling on installations where mandatory inspections are not required may not commence before 2:00 p.m. Failure to observe this requirement may result in the suspension of the Licensed Master Plumber's privilege to self-inspect. The Licensed Master Plumber must comply with all DOT requirements.

(i) Water sampling test. Before taps are installed in a new internal water main, the main must pass a water sampling test. The main must be disinfected and a satisfactory water sample must be obtained by the Contractor in the presence of the Department representative only. A water sample will be considered satisfactory if it is free of bacteria, with acceptable color, odor, taste, temperature, turbidity, and has measurable residual chlorine, as determined by the Department.

(Amended City Record 7/26/2021, eff. 8/25/2021)

(a) Water use restrictions. The use of water is permitted, subject to the following restrictions:

(1) Prohibition of Use as a Source of Energy. The use of the pressure or flow of water as a source of energy is prohibited, except when specifically approved by the Department or for charging the battery of an electronic plumbing fixture.

(2) Restrictions on Use for Coolant Purposes. The use of City water for coolant purposes in industrial and commercial equipment is prohibited, except with the use of an approved "water conservation device," in accordance with 15 RCNY § 20-06.

(3) Required Recirculation in Fountains, Ornamental Pools, Aquariums and Similar Structures. Display fountains, ornamental pools, aquariums, and similar structures using water in excess of the rate of one-half (1/2) gpm shall be recirculated.

(4) Shutoffs Required for Drinking Fountains and Recreational Sprinklers. Drinking fountains shall operate only when activated by a user. Recreational sprinklers shall be equipped with a timer to stop flow if the sprinkler is not being used or shall not operate when not in use.

(5) [Reserved.]

(6) Watering of lawns and gardens.

(i) The use of a hose, automatic sprinkler or other means to water lawns or gardens is prohibited between the hours of 11:00 a.m. and 7:00 p.m. Automatic irrigation systems shall include a sensor or control which shall prevent operation during or within 24 hours of substantial rain.

(ii) Between the first day of November and the last day of the following March, the following activities are prohibited using City water: (a) the use of hoses and sprinklers, and (b) the watering of lawns and gardens, except for the watering of non-turf plants with a hand-held container.

(iii) The following activities are prohibited at all times: (a) the use of hoses which flow at more than five (5) gpm at sixty (60) psi or which, regardless of flow rate, are not equipped with an automatic shutoff mechanism which will turn off the flow of water if a handle or trigger is not actively held or compressed, and (b) the practice of allowing sprinklers to flood sidewalks, gutters and roadways.

(7) Sidewalks flushing. The flushing of sidewalks is prohibited between the hours of 11:00 a.m. and 7:00 p.m. In addition, the flushing of sidewalks by means of a hose or piping is prohibited between the first day of November and the last day of the following March. This provision, however, shall not be construed to prohibit the washing of such surfaces, particularly the exterior surface of a building, where such washing is required as part of repairs mandated by the Administrative Code or to protect the health and safety of the public. For one, two, or three-family homes, any hose used to supply City water for sidewalk cleaning purposes must be equipped with a nozzle which limits flow to no more than five (5) gpm at sixty (60) psi and which is equipped with an automatic shutoff mechanism which will turn off the flow of water if a handle or trigger is not actively held or compressed. For multiple dwellings, commercial occupancies, or where required by the Administrative Code or by the Department for health and safety purposes, any hose used to supply City water for sidewalk cleaning purposes shall use a fixture that flows at no more than 2.5 gpm, irrespective of pressure.

(8) Temporary Suspension of Permission to Use City Water for Purposes Listed in paragraphs (6) and (7). The Commissioner may suspend the authorization granted herein for the flushing of sidewalks and the watering of lawns and gardens. Such a suspension may be implemented without formal notice, through advisories issued via broadcast or print media. Upon the declaration of either a Water Pressure Alert or a Water Pressure Emergency, the use of City water to flush sidewalks and to water lawns or gardens is prohibited until the alert/emergency has ended.

(9) Car washing.

(i) The use of City water for commercial car washing purposes is prohibited, except (a) where at least seventy-five (75) percent of the water is reused by means of a recirculating system which uses City water for the final rinse only, or (b) where coin operated automatic high pressure equipment is employed. Any premise using City water for commercial car washing must install an approved backflow prevention device.

(ii) Garages, gasoline service stations, and other similar establishments which furnish car washing as part of their regular service and do not employ automatic car washing equipment, as described above, may use buckets of water only.

(iii) Any hose used to supply City water for non-commercial car washing purposes must be equipped with a nozzle which limits flow to no more than five (5) gpm at sixty (60) psi and which is equipped with an automatic shutoff mechanism which will turn off the flow of water if a handle or trigger is not actively held or compressed.

(b) Fire hydrant use.

(1) Fire hydrants on the raw may be routinely opened only by authorized employees of the Department and/or the Fire Department. All others seeking permission to open a fire hydrant must secure a permit from the Department, Bureau of Customer Service. Fire Hydrant Use Permits shall be secured at the site where water is being used. Permits for the use of hydrants may not be granted when, in the view of the Department, water from a metered source is available to serve the end use described in the permit application. Permit applicants are required to describe the proposed use in detail and indicate why another alternative (e.g., existing metered source or construction meter) cannot be used. Only approved hydrant wrenches may be used. Water must be obtained from the smaller size hydrant nozzle only. Caps and chains are not to be broken and must be securely replaced after use.

(2) Fire Hydrant Use Permits are valid only on the days specified therein, unless otherwise approved by the Department.

(3) Permits shall not be issued for use of fire hydrants supplied by water mains which are twenty (20) inches or larger in diameter. Fire hydrants may not be obstructed, and shall be available, at all times, for use by the Fire Department.

(4) With the exception of hoses used to extinguish fires, any hose connected to a fire hydrant must be equipped with an approved Reduced Pressure Zone backflow prevention assembly (RPZA). Applications which do require a RPZA include, but are not limited to, demolition dust control, pavement breaking, cutting and sawing, mixing and curing of concrete or mortar, well digging, washing/pumping of manholes, basements or sewers, application of pesticides, herbicides, paints, curing agents or fertilizers, washing down roadway construction, or make-up water. (See Appendix Figure #6).

(5) Connections to fire hydrants shall be made by valve and couplings which can be readily detached in case of emergency. Where valve and couplings are used, the hydrant must be fully open at all times. The rate of flow shall be governed by the installed valve, and all such connections shall be uncoupled immediately after use.

(6) All fire hydrants used during the period from November 1st to April 15th shall be pumped out immediately after use. Hydrants Use Permits shall be invalid when the temperature is below thirty-two (32) degrees Fahrenheit.

(7) Defective hydrants shall immediately be reported to the Department by the permit holder.

(8) Opening a fire hydrant without a permit shall be a violation.

(c) Installation and maintenance of corporation stops (taps), wet connections, service pipes and curb valves.

(1) Installation and maintenance. The property owner shall be responsible for installation and maintenance of corporations stops (taps), wet connection sleeves and valves, three-ways, service pipes, and curb valves.

(2) Shut-off charges. Should the Department shut a tap because of a leaking service pipe, non-payment of a bill, denial of access for an inspection or meter replacement or repair, failure to make repairs required for the installation or replacement of a meter, or non-compliance with Department rules, the owner shall pay a shut-off charge in accordance with the Water and Wastewater Rate Schedule of New York City Water Board.

(Amended City Record 7/26/2021, eff. 8/25/2021)

Any person who is in violation of or fails to comply with any provision, standard or requirement of these Rules or the terms and conditions of any permit issued pursuant to these Rules shall be subject to the issuance of notice(s) of violation and other civil or criminal enforcement action(s) pursuant to the provisions of § 24-346 of the Administrative Code of the City of New York, including but not limited to payment of civil penalties and compliance with orders of the Commissioner and/or the Environmental Control Board. In addition to any civil and criminal enforcement pursuant to § 24-346 of the Administrative Code of the City of New York, the Department may refuse to issue permits to any person who is in violation of, or fails to comply with, any provision, standard or requirement of these Rules or the terms and conditions of any permit, in accordance with 15 RCNY § 20-01(c).

For the purposes of "The Rules Governing and Restricting the Use and Supply of Water", the following definitions shall apply:

Aesthetically objectionable. A condition which could be objectionable to other water consumers, but would not adversely affect human health. Substances such as food-grade dyes, hot water, and stagnant water from fire lines in which no chemical additives are used may result in aesthetically objectionable conditions.

Air gap separation. Air Gap Separation means the unobstructed vertical distance through the free atmosphere between the lowest opening from any pipe or faucet supplying water to a tank, plumbing fixture, or other device and the flood level rim of the receptacle. The differential distance shall be at least double the diameter (D) of the supply pipe. In no case shall the air gap be less than 1 inch.

Applicant. Any person applying for a permit pursuant to these Rules.

AMR – Automatic Meter Reading. The use of radio or telephone-based technology to read water meters.

ANSI. The American National Standards Institute.

ASCII. American Standard Code for Information Interchange.

ASTM. The American Society for Testing Materials.

Automatic water regulating device. A self regulating valve or other device, the purpose of which shall be to limit the maximum use of City water on air conditioning and refrigeration units that do not have a water conserving device to 1.5 gpm per ton of refrigeration or air conditioning.

AWWA. The American Water Works Association.

Backflow prevention device. An approved air gap, reduced pressure zone (RPZ) device, or double check valve assembly (DCV) used to contain potential contamination within a facility.

Backflow. The flow of water or other liquids, mixtures, or substances into the distributing pipes of a potable supply of water from any source or sources other than its intended source. Backsiphonage is one type of backflow.

Ball valve. A valve capable of regulating, stopping or starting flow with a one-quarter (90°) turn of the valve by means of a movable ball which fits in a spherical seat.

BCS. Bureau of Customer Services.

Booster system. A pumped system used to deliver water at a higher pressure within a building.

Building. An enclosed structure having a specific block and lot (or tax sub-lot) and a separate entry from the street or an outdoor area.

City. The City of New York.

City water. Water supplied by the City of New York.

City water main. A water main owned and maintained by the City of New York under the jurisdiction of the Department.

Combined service. A water service which supplies both domestic and fire suppressions end uses and the fire protection requirements exceed the domestic demand and determine the size of the service.

Commissioner. The Commissioner of the New York City Department of Environmental Protection.

Completed meter permit. A meter permit returned to the Department that indicates the meter size, type, serial number, remote identification number, meter and remote receptacle location, and date of installation that has been signed and sealed by the licensed plumber and lists the licensed plumber's business address.

Connection. A water service pipe which connects the customer or a development to a City Water Main, Private Water Main, or Internal Water Main.

Cross connection. An actual connection or a potential connection between any part of a potable water system and any other environment that would allow substances to enter the potable water system. Those substances could include gases, liquids, or solids, such as chemicals, water products, steam, water from other sources (potable or nonpotable), or any matter that may change the color or add odor to the water. Bypass arrangements, jumper connections, removable sections, swivel or changeover assemblies, or any other temporary or permanent connecting arrangement through which backflow may occur are considered to be cross connections.

Curb valve. A shutoff valve on the service connection in the sidewalk area outside the property, generally located eighteen (18) inches from the curb line.

Customer. Any person to whom City water is supplied.

Day. Except as otherwise stated, day shall refer to calendar day.

DDC. New York City Department of Design and Construction.

Department or DEP. The New York City Department of Environmental Protection.

Distribution piping. All piping downstream of the water meter setting.

Degree of hazard. The assessment or evaluation of a facility's domestic water system's cross-connections as they relate to the health hazard of the consumers of water. A facility may be rated Hazardous, Aesthetically Objectionable or Non-Hazardous.

Department. The New York City Department of Environmental Protection.

Disinfection. Chlorination in accordance with methods approved by the Department.

Domestic service with sprinkler heads. A domestic service sized for domestic demands which has been approved by the Department of Buildings to supply a limited number of fire sprinkler heads.

Domestic use. Water consumed for purposes other than extinguishing fire.

DOT. New York City Department of Transportation.

Double check detector assembly. A device consisting of two (2) single independently acting check valves, suitable connections for testing the water tightness of each valve, and a by-pass meter that shows whether flow has occurred from the water service connection into the premises, and a small double check valve housed together as one assembly.

Double check valve assembly. A backflow prevention consisting of two internally loaded independently operating check valves, located between two tightly closing resilient-seated shutoff valves with four properly placed resilient-seated test cocks. This assembly shall only be used to protect against a non-health hazard (i.e., a pollutant).

Drip line. The outer circumference of a tree's branches and the farthest point where water drips from the tree branches onto the ground.

Electronic meter (electromagnetic meter). A meter that operates using Faraday's Principle.

Encoder-Register. A device from which electronic meter reading data can be obtained from the meter semiautomatically and at a remote location.

Fee. A charge determined by the New York City Water Board.

Fire department. The New York City Fire Department.

Fire service meter. A water meter certified by an AWWA standard for such meters and approved by the Department for use on a service, subject to fire service flows.

Fire pump. A pump installed on a service connection to insure adequate flow for purposes of fire protection system.

Fire service. A service connection that supplies water exclusively to a fire protection system (sprinkler, standpipe, combination of sprinkler and standpipe or hydrant).

Fixture units. A measure of the probable hydraulic demand on the water supply by various types of plumbing fixtures.

Flood level rim. The edge of the receptacle from which water overflows.

Flushometer valve. A device which discharges a predetermined quantity of water to fixtures (urinals / tankless toilets) for flushing purposes and is actuated by direct water pressure.

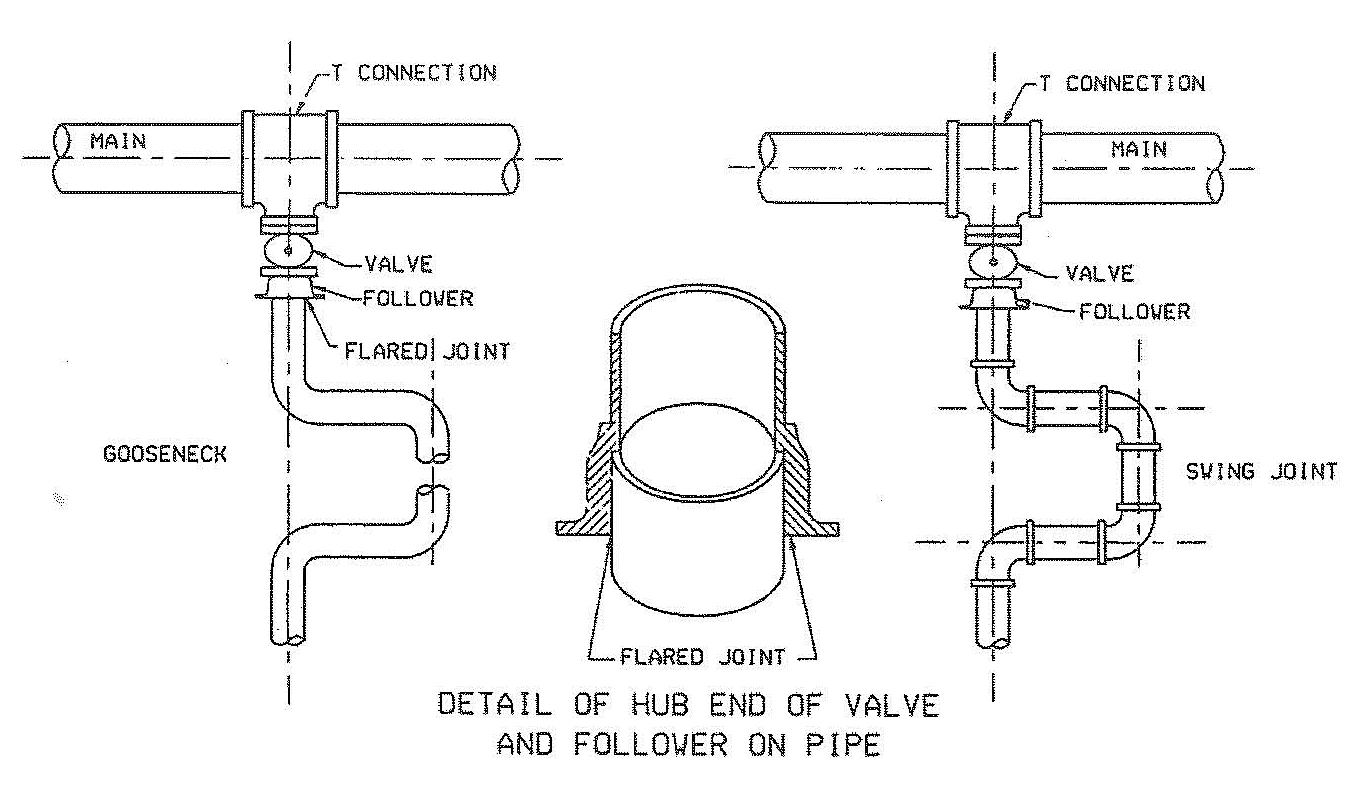

Gooseneck. An extra three (3) to five (5) feet of water service connection installed to the right of the corporation stop (tap) when facing the corporation stop (tap). (See Appendix Figure #2).

G.P.M. (gpm). The rate of flow of water in a service connection, or through a meter or a pump, measured in gallons per minute.

Hazardous facility. A facility in which substances may be present that may endanger the health of other customers if introduced into the public water system. Examples include: laboratories, sewage treatment plants, chemical plants, hospitals, and mortuaries.

House tank (roof tank). An elevated water storage tank used to feed domestic and/or fire systems, which is usually located on the roof.

Hydrant. A standard New York City fire hydrant.

I.D. The inside diameter of a pipe.

Inspection. An investigation and review, by the City, of work performed by others under a permit by the Department, and which is evidenced by a certificate of inspection.

Internal fire protection system. A fire pump system, a sprinkler system, a standpipe system, combination sprinkler and standpipe system, or any fire suppression system approved by the Department of Buildings.

Internal water main. A water main constructed by a private entity in private property and not in a mapped street, record street or a street for which an opinion of dedication has been issued. Internal water mains are under the jurisdiction of the Department from the City or private water main up to and including the meter.

Irrigation system. Connection used to supply water to vegetation.

Jacketed pipe insulation. Pipe insulation with a covering design to retard vapor infiltration into the insulation and for protection against physical abrasion and damage.

Licensed master plumber. A plumber licensed by the City agency having jurisdiction over such licenses to perform plumbing work within New York City.

Mapped street. A street that appears on the official map of New York City.

Meter. An instrument for measuring amounts of water consumed.

Meter register. The system component that converts the movement of the meter's impeller, turbine, or disc into an electronic signal or display. This component consists of a meter register and a signal (data) encoder assembly, and is assembled as either a single unit, or as separate units to be mounted on the meter.

Meter set date. The date the meter is installed.

Meter setter / resetter. A shop or factory-fabricated set of piping, valves and an electrical continuity bar installed as a unit designed to hold a water meter of two (2) inches or less in diameter.

MTU. Meter Transmitter Unit. An electronics box wired to the water meter. The MTU is part of the AMR system programmed to read the meter and transmit radio frequency readings to a remote receiving unit.

New York City Water Board. A corporate municipal instrumentality of the State of New York established by Chapter 515 of the Laws of 1984 which is authorized to establish and collect fees, rates and other service charges for use of, or for services furnished by, the New York City water and sewer systems.

Non-turf plants. Plants other than a lawn.

Nozzle. A spring loaded self-closing device used for controlling the flow of water from a hose.

Offset swing joint. An installation consisting of three (3) lengths of pipe and four (4) elbows which are installed in lieu of a gooseneck. (See Appendix Figure #2.)

OSHA. The Occupational Safety and Health Administration of the United States Department of Labor.

OS&Y valve. The outside stem and yoke valve used on fire lines.

Person. An individual, partnership, company, corporation, association, organization, governmental agency, administration, department, any other group of individuals, or an officer or an employee thereof.

Pit meter. A water meter installed in an outside pit or vault.

Private water main. A water main constructed by a private person in the bed of a final mapped street or record street.

Professional engineer. An engineer licensed by the New York State Education Department to practice professional engineering in New York State.

psi. The static pressure of water within a closed piping system, or the loss of water pressure due to flow through a piping system, flow control devices or flow measuring devices, measured in pounds per square inch.

Record street. A street that appears on the Tax Map of the City but may not be a mapped street.

Reduced Pressure Zone (RPZ) Device. A backflow prevention device assembly consisting of a mechanical, independently acting, hydraulically dependent relief valve, located between two independently operating, internally loaded check valves that are located between two tightly closing resilient-seated shutoff valves with four properly placed resilient-seated test cocks. This assembly shall be tested at least annually and is suitable for direct high hazard cross-connections.

Reduced pressure principle detector assembly (RPDA). A specially designed assembly composed of a line-size approved reduced pressure principle backflow prevention assembly with a bypass containing a specific water meter and an approved reduced pressure principle backflow prevention assembly specifically designed for such application. The meter shall register accurately for very low flow rates of flows up to 2 gallons per minute and shall show registration for all rates of flow. This assembly shall be used to protect against a health hazard (i.e. containment) on fire protection services only.

Registered architect. A person licensed by the New York State Education Department to practice architecture in New York State.

Relay. Replacement of an entire water service connection without replacement of the corresponding corporation stop (tap) or wet connection.

Remote read resolution. Refers to the smallest increment of water volume provided in the meter reading transmitted to a remote location. For example, a water meter may generate a reading in cubic feet, units of tens of cubic feet, or units of hundreds of cubic feet.

Remote receptacle. A system component at a location away from the meter that receives the probe of a portable visual-display unit, or a portable meter reading unit.

Rodding. The installation of steel rods in order to secure and prevent movement of joints, valves, caps, plugs, fittings and accessories.

Sealed Building. A building with windows and doors which are locked and covered or blocked by concrete block, bricks, sheet metal or other materials intended to prevent access. Windows covered with wooden boards shall not constitute a sealed building.

Sidewalk valve. A valve on a domestic service pipe located in the sidewalk area, at a distance of two (2) feet (street side) from the property line.

Stuffing box. That part of a valve which contains packing or similar material which prevents leakage when the valve is operated.

Suction tank. A tank used to protect the City distribution system from a large, sudden water demand.

Swing joint connection. An acceptable method of connecting to either well water or City water.

Tap. A corporation stop approved by the Department which controls the flow of water.

Tax lot. A portion or parcel of land classified as such by the Department of Finance.

Tee connection. A three-way pipe fitting installed in a private water main or internal water main in lieu of a tap or wet connection.

Test tee. A downward pointing plain tip faucet or hose connection located after the water meter but before the meter outlet valve that is used for connecting an outlet hose for meter accuracy testing.

Title vested street. A mapped street or record street whose ownership has been accepted by the City of New York, or a street which has a Corporation Counsel Opinion of Dedication.

UL/FM. Underwriter's Laboratories/Fireman's Mutual.

Vacant building. A building which is not inhabited, or is occupied illegally.

Valve. A non-rising stem gate valve or full port ball valve.

Valve box. A standard New York City valve enclosure including the skirt, head and cover.

Waiver. The act of intentionally relinquishing a right or privilege.

Water conserving device. With reference to air conditioning or refrigeration systems, an evaporative condenser, water cooling tower, spray pond or economizer.

Water meter accuracy testing ("meter testing"). Refers to testing the accuracy of a water meter in the field, on an indoor test bench, using methods designed by the Department and in conformance with AWWA's Manual M6: "Water Meters – Selection, Installation, Testing and Maintenance."

Water meter setting. The water meter, inlet and outlet isolation valves, test tee, and associated approved piping and fittings.

Water outlet. An orifice through which water is supplied to a fixture, into the atmosphere, to a boiler or heating system, or to any device which requires water to operate.

Water service connection. A water supply pipe which connects the customer or a development to a City water main, private water main or internal water main. Service connections connecting a single customer's premises to a City water main or a private water main or internal water main are under the jurisdiction of the Department from the City water main or private water main or internal water main up to and including the meter outlet valve in metered properties, or the first valve within the property in unmetered properties.

Wet connection. The hardware required to install a connection larger than two (2) inches without interruption of water service. A wet connection shall consist of a sleeve and a corresponding valve approved by the Department.

(Amended City Record 7/26/2021, eff. 8/25/2021)

Appendix

TABLES FOR 15 RCNY CHAPTER 20

Table 1

Fixture Units – Table of Equivalents

Fixture Units – Table of Equivalents

Fixture | Dwellings | Commercial/Industrial Buildings |

Fixture | Dwellings | Commercial/Industrial Buildings |

Kitchen & Laundry | ||

Kitchen Sink | 2 | 4 |

Laundry Tray (1 to 3 Sections) | 3 | 3 |

Dishwasher (1/2 Inch Outlet) | 1 | 4 |

Washing Machine (Automatic) | 2 | See Commercial Washing Machine Fixture Units Below |

Bathroom, Washroom & Shower | ||

Bathroom Group: (Toilet, Sink & Tub/Shower) | ||

(a) Tank | 6 | 11 |

(b) Flush Valve | 8 | 15 |

Toilet | ||

(a) Tank | 3 | 5 |

(b) Flush Valve | 6 | 10 |

Wash Basin | 1 | 2 |

* Bath Tub | 2 | 4 |

* Shower | 2 | 4 |

Urinal | 3 | 6 |

Commercial Washing Machine & Other Plumbing Outlets | ||

Cold Water Only - 5/8 Inch & Smaller | 1 | 2 |

Hot & Cold Water - 5/8 Inch & Smaller | 2 | 4 |

Cold Water only - 3/4 Inch | 2 | 4 |

Hot & Cold Water - 3/4 Inch | 4 | 8 |

Cold Water Only - 1 Inch | 3 | 6 |

Hot & Cold Water - 1 Inch | 6 | 12 |

* A bath tub and the shower over it are considered to be a single fixture.

Table 2

Conversion of Fixture Units to Rate of Flow

Conversion of Fixture Units to Rate of Flow

Fixture Units | Rate of Flow | |

Premises with more than 20% flushometers | Premises with less than 20% flushometers | (gpm) |

Fixture Units | Rate of Flow | |

Premises with more than 20% flushometers | Premises with less than 20% flushometers | (gpm) |

– | 10 | 8 |

– | 15 | 12 |

– | 20 | 15 |

5 | 30 | 20 |

10 | 40 | 25 |

15 | 60 | 33 |

25 | 80 | 39 |

35 | 108 | 43 |

50 | 125 | 49 |

65 | 150 | 55 |

75 | 175 | 60 |

90 | 200 | 64 |

100 | 210 | 66 |

110 | 225 | 70 |

125 | 250 | 74 |

150 | 270 | 78 |

175 | 300 | 83 |

200 | 340 | 92 |

250 | 375 | 100 |