Loading...

A. All work, unless otherwise specified, shall be done in accordance with the current edition of the Caltrans Standard Plans and Specifications and the Contra Costa County Standard Plans. Caltrans and Americans with Disabilities Act standards apply where applicable.

B. If work is not being conducted in a safe manner, or is not in conformance with the approved design, specifications and standards, or with other conditions of the permit, the city may issue a stop work order. Permit holder shall indicate to the city how he or she plans to remedy the violation, and shall not resume work or make corrections until the city releases the stop work order in writing. The city reserves the right to add or modify conditions to the initial permit in order to prevent future violations.

C. All work authorized by the permit shall be performed in a good and workmanlike, diligent, and expeditious manner, and must be completed to the satisfaction of the city engineer.

D. Permittee shall restore trenches and street surfaces in accordance with city requirements, including achieving the required compaction of all trench and surface sections. At the city's discretion, compaction testing may be required. A two-sack sand slurry mixture may be required for compaction where excavation interferes with traffic flow or where work is within the roadway portion of an intersection. Permittee shall acquire and pay for all services needed to perform the required compaction test and retest until the desired compaction is achieved.

E. Any street paved or resurfaced in the previous thirty-six months shall be termed "prohibition streets" and shall be subject to special paving requirements.

F. During construction or installation, permittee shall maintain the site in a safe and clean condition, free of dust, debris, dirt, siltation, concentrated runoff, and other nuisances. Noise shall be kept to a minimum. Excavations shall be covered and/or barricaded at the city's direction at the end of each work day. Barricades and reflectors shall be used to mark obstructions. All barricades must have portable flashers unless otherwise specified. Access to adjacent properties shall not be unreasonably restricted. Excavations for sidewalks may remain open for up to two days with proper barricades. Excavations for driveway approaches may remain open for up to two days with proper barricades and permission of property owner.

G. Per city of Pinole Municipal Code Chapter 8.20, permittee shall implement and maintain measures to keep sediment, wash waters, equipment maintenance products, and other construction related materials debris from entering the storm drainage system. Dumping or discharge into the city's storm drainage system is prohibited. Measures to protect the storm drainage system shall be in place prior to start of work. Permittee shall implement the Contra Costa Clean Water Program's Pollution Prevention Program Best Management Practice (BMP) guidelines.

H. In every case, the permittee shall be responsible for restoring to its former condition as nearly as may be possible any portion of the city right-of-way which has been excavated or otherwise distributed by permittee. The permittee shall maintain the surface over facilities placed under any permit. If the right-of-way is not restored as herein provided, and if the city elects to make repairs, permittee agrees by acceptance of permit to bear the cost of the restoration work. Plan shall also include work days, duration and hours of operation, and impacts on and provisions for on-street parking. Incomplete plans will be rejected.

I. If any future construction, reconstruction, or maintenance work by the city or required by the city on a street requires the relocation, removal, or abandonment of installations or encroachments in, on, over, or under a street, the permittee owning, controlling, or maintaining such installations or encroachments shall relocate, remove, or abandon the same at his or her sole expense unless otherwise required by law. When removal, relocation, or abandonment is required, the city engineer shall give such permittee a written demand specifying the place of relocation, or that the installations or encroachment must be removed or abandoned. If said permittee fails to comply with said instructions, the city may cause the removal, relocation, or abandonment of the encroachment at the expense of the permittee.

J. The permittee shall ascertain the exact location of all underground facilities prior to doing work that may be damaged during construction. The permittee is responsible for verifying that all utilities including water, cable TV, electrical, gas, telephone, sewer, fiber optic, gasoline and other city facilities are clear, protected, or relocated from the area of work prior to construction. Forty-eight hours before commencing work, the permittee shall contact Underground Service Alert (USA) at 811, 1-800-227-2600, or online at usanorth811.org to verify elevations and locations of all existing utilities. Additional potholing of critical utilities shall be performed by permittee at permittee's expense if there is uncertainty regarding possible conflicts.

K. Permittee shall remove all painted utility markings associated with the project when the job is completed at the city's direction. Depending on the location, the city may require applicant to ensure a uniform right-of-way appearance after the markings are removed. This may include, but is not limited to, cleaning an entire flag of sidewalk or asphalt.

L. Permittee shall adhere to the pavement restoration regulations established in Section 12.04.090.

M. If all the construction and/or repair work is not completed within the time limit set on the permit, the city engineer is authorized to have the same done at the expense of the permittee. No new permits shall be issued to an individual or company who has not reimbursed the city for all of its expenses in completing work under this provision.

N. A permit shall become void if work is not commenced within thirty calendar days of its issue.

O. The permittee shall call for and secure a preliminary inspection of grading and form work before placing any concrete, and he or she shall call for a final inspection upon completion of the work. The permittee shall be responsible for removing all surplus and waste material from the job site and for the restoration of the work area to a clean and satisfactory condition.

P. The city engineer shall have the power and authority to determine that the use for which a driveway was constructed has been abandoned, and give written notice requiring that the curb and gutter and sidewalk shall be constructed to grade. (Ord. 2022-03 § 2 (part), 2022; Ord. 217 § 6, 1965).

A. All occupation of street parking spaces by permittee shall be approved by city in the encroachment permit.

B. Any occupancy of parking spaces should occupy only the parking lane (width of eight feet or less), shall occupy the minimal necessary length, shall not block gutter drainage flow, and shall not restrict flow of adjacent street traffic or provide an unsafe condition for vehicular traffic due to reduced lane width or impaired visibility.

C. All occupancies in the parking area shall be fitted with reflectors on the structure or on barricades.

D. The city may place restrictions on the duration of all such occupancies.

E. Permittee agrees to pay for utilization of any metered parking for as long as the parking spaces are not available for public use. The fees shall be based on the current meter rate or fee schedule.

F. For non-metered public parking spaces utilized during construction, the permittee shall place temporary "No Parking" signs. (Ord. 2022-03 § 2 (part), 2022).

A. The final appearance of the street after the repairs are made should be acceptable with an engineered appearance. Street repairs that are satisfactory from a functional point of view may produce a negative reaction from the public if they give the appearance of being poorly planned or executed. The public's perception of street repairs is based primarily on shape, size, orientation, and the geometry of the patch.

B. Street repairs should leave a pavement in a condition at least as good as, if not better than, the condition prior to the repairs. In the case of major projects that involve excessive haul of materials or unusually heavy construction equipment or activity, non-destructive testing of the pavement condition before and after construction may be required at the city's discretion.

C. Excavations and street repairs, even well-constructed street repairs, shorten a pavement's life. Several types of street distress, settlement, alligator cracking, and potholes, often show up around patches. Quality street repairs should attempt to reduce the occurrence of these types of distress.

D. Avoid weakening or destroying the existing pavement around an excavation with heavy construction equipment, stockpiling, or delivery of materials, etc. When damage does occur, remove the damaged pavement, extending the limits of the street repair, before replacing the pavement. No stockpiling of backfill or road building materials is permitted on the pavement.

E. Contractors must adhere to the following pavement restoration guidelines:

1. Pavement shall be cut to a single, vertical line prior to excavation.

2. All excavated material shall be removed from the job site within twenty-four hours.

3. Any trench extending from the curb into the parking lane will require a complete two inch grind and overlay of the parking lane for twenty-five feet in each direction. All trenches extending into the traveled lane transversely will require the entire length of the trench up to the nearest lane line to be cold milled two inches and overlaid twenty-four feet in both directions from the center line of the trench.

4. Every trench must be backfilled or covered by trench plates the same day. Trenches can be backfilled with class 2 aggregate base as specified in the Caltrans Standard Specifications, Section 26, "Aggregate Base."

5. After a trench has been backfilled, and immediately prior to placing asphalt concrete, the existing asphalt concrete shall be saw cut, or milled to a vertical face. The cut shall be a "T-cut" and the new asphalt concrete paving shall be butt joined to the existing asphalt concrete vertical face. No feathering of new paving to existing paving is allowed. The vertical faces shall be tack coated.

6. In prohibition streets, placement of the final two inches of asphalt concrete wearing surface shall be done by a paving machine or a spreader box.

7. To allow for proper placement of the new pavement section, damaged pavement outside of the original trench cut lines shall be removed by cutting in lines perpendicular to or parallel to the original trench lines. No diagonal cuts are to be made. Undamaged pavement of three feet or less between two damaged areas shall also be removed.

8. For trenches in recently paved prohibition streets, the entire lane shall be key-cut two inches deep, and repaved with asphalt concrete unless the engineer gives written authorization to resurface with a polymer modified slurry seal instead. Authorization from the engineer to use slurry seal instead of asphalt concrete shall set forth the reasons for the authorization.

9. For trenches in recently slurry sealed prohibition streets, the entire lane shall be resurfaced with polymer modified slurry seal.

10. Trenches in concrete streets shall be repaved with concrete. The thickness of the new pavement shall be equal to the thickness of the existing pavement with the minimum thickness to be six inches in the roadway.

11. Trenches in arterial and collector streets shall be paved with not less than six inches asphalt concrete or match the existing pavement thickness (whichever is greater).

12. Pavement shall be restored within fourteen working days from the time the entire trench is backfilled, unless delay is excused due to circumstances beyond the contractor's control, such as inclement weather. For minor excavations such as service installations, the pavement shall be restored with in thirty working days from the time the entire trench is backfilled, unless delay is excused due to circumstances beyond the contractor's control, such as inclement weather.

13. Asphalt pavement shall be compacted to obtain a minimum of ninety-five percent relative compaction. The asphalt concrete wearing surface shall have no irregularity greater than five-sixteenths of an inch in ten feet in any direction.

14. On all streets steel plates shall be used to facilitate traffic flow and to protect the excavation until finish pavement is restored. Steel plates used to bridge a street opening shall be ramped to the elevation on the adjacent pavement and secured against movement in any direction. Temporary ramps shall be constructed of asphalt and shall have a gradual 30:1 slope or flatter using asphalt cutback.

15. All painted USA markings shall be removed by the permittee after the work has been completed.

16. All damaged pavement markings and striping shall be replaced and restored by the permittee.

F. Example of Repair Details.

1. Existing pavements should be removed to clean, straight lines parallel and perpendicular to the flow of traffic. Do not construct patches with angled sides and irregular shapes. All patches that exceed fifty percent of the transverse pavement width shall be full lane width and the non-patched areas shall be milled and resurfaced.

2. Avoid patches within existing patches. If this cannot be avoided, make the boundaries of the patches coincide. All repairs should be full lane width.

3. Do not leave strips of pavement less than one-half lane in width from the edge of the new patch to the edge of an existing patch or the lip of the gutter.

4. In concrete pavements, remove sections to existing joints, or new saw cut joints at midslab, that is in good repair. In damaged concrete, the limits of removal should be determined in the field by city inspector.

5. Asphalt and concrete pavements should be removed by saw cutting or grinding. Avoid breaking away the edges of the existing pavement or damaging the remaining pavement with heavy construction equipment. Patches should have a smooth longitudinal grade consistent with the existing roadway. Patches should also have a cross slope or cross section consistent with the design of the existing roadway.

6. In the case of a series of patches or patches for service lines off a main trench, repair the pavement over the patches by grinding and overlay when the spacing between the patches is less than ten feet. In cases where the existing pavement is in poor condition (in the upcoming years resurfacing contract) and may require overlay within the next few years, this requirement may be modified or waived by the city engineer.

7. A patch should provide a smooth ride with smooth transitions on and off the repair and all joints should be located outside the wheel path. Overlays should be placed by first removing the existing pavement to the desired depth by grinding or milling, and then placing the pavement flush with the adjacent surfaces.

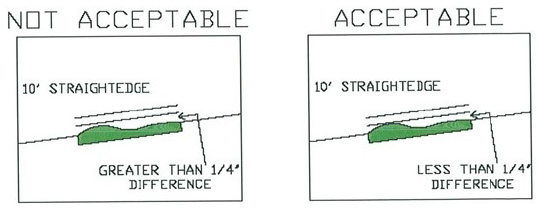

8. Surface tolerances for street repairs shall meet the standards for new construction. The finished surface of the pavement repair should be tested with a ten foot straightedge parallel to the centerline or perpendicular across joints. Variations measured from the testing face of the straightedge to the surface of the street repair should not exceed one-quarter inch.

9. Transverse patches on arterial and collector streets shall be overlaid across the entire street width for a distance of two feet minimum on all sides of the trench using a T-patch.

10. Do not allow the edges of patches to fall in existing wheel paths. The edges of patches parallel to the direction of traffic shall be limited to the boundaries of lanes or to the centerline of travel lanes.

11. When the proposed excavation falls within ten feet of a section of pavement damaged during the utility repair, the failed area shall be removed to sound pavement and patched. Scarring, gouging, or other damaged pavement adjacent to a patch shall be removed and the pavement repaired to the satisfaction of the city inspector. Damaged pavement within ten feet of a patch must also be patched.

12. Patches must avoid frequent width changes.

(Ord. 2022-03 § 2 (part), 2022).

A. Permittee shall notify the city forty-eight hours prior to starting work under the permit.

B. Permittee shall not work on Saturdays, Sundays, city of Pinole holidays nor between the hours of 5:00 p.m. and 8:00 a.m. without the written permission of the city engineer.

C. All work shall be subject to monitoring, inspection, and approval by the city. It is the permittee's obligation to determine from the inspector what stages of frequency of inspection will be required. Requests for inspection shall be made at least 48 hours in advance. All form work and subgrade shall be inspected by the city prior to the placement of concrete or asphalt concrete. All pipelines and other underground facilities shall be inspected by the city prior to covering. Permittee shall request a final inspection and acceptance of the work.

D. All work shall be planned and carried out with the least possible inconvenience to traveling public. The permittee shall assign properly trained and attired flagger(s) to direct traffic. Traffic shall not be unreasonably delayed. Flagging operations shall be in conformance with the Traffic Manual, flagging control chapter. Construction operations shall be conducted in such a manner as to cause as little inconvenience as possible to the abutting property owners. All work shall be subject to suspension if traffic delays are excessive.

E. Contractor shall request and obtain approval from the city engineer before any lane closures are implemented. Road closures shall not be permitted unless approved in writing by the city engineer. No open excavation shall be left unattended at any time.

F. Upon completion of the work, all brush, timber, scraps, material, etc., shall be entirely removed and the right-of-way shall be left in as presentable a condition as existed before work started. Removal of the encroachment shall be at applicant's expense and public facilities shall be restored to the satisfaction of the city engineer.

G. Permittee will properly maintain any encroachment in a safe and aesthetically acceptable condition for the duration of the occupancy. Inspection and repair of any damaged city facility resulting from the work under the permit shall be at the expense of the permittee.

(Ord. 2022-03 § 2 (part), 2022; Ord. 217 § 9, 1965).

Any person, firm or corporation violating any of the provisions of this chapter, or of the codes adopted under this chapter, shall be deemed guilty of a misdemeanor and, upon conviction thereof, shall be punishable by a fine of not more than five hundred dollars or by imprisonment in the county jail for not more than six months or by both such fine and imprisonment. (Ord. 2022-03 § 2 (part), 2022; Ord. 217 § 10, 1965).