The City Utilities Board Fats, Oils and Grease Management Policy is established under North American Industry Classification System (NAICS) guidelines to prohibit obstruction and interference to the publicly owned treatment works.

(A) Scope and purpose. To prevent sanitary and combined sewer system blockages, obstructions and overflows due to the contribution and accumulation of fats, oils and grease (FOG) from food service establishments, commercial facilities and industrial facilities.

(B) Definitions. For the purpose of this section, the following definitions shall apply unless the context clearly indicates or requires a different meaning.

FATS, OILS AND GREASE (FOG). Organic polar compounds derived from animal and/or plant sources. FOG may be referred to as “grease” or “greases” in this section.

FOOD SERVICE ESTABLISHMENT (FSE).

(a) Any establishment, business or facility engaged in preparing, serving or making food available for consumption. Single-family residences are not a FSE, however, multi-residential facilities may be considered a FSE at the discretion of the Director.

(b) FOOD SERVICE ESTABLISHMENTS will be classified as follows:

1. CLASS 1. Deli - engaged in the sale of cold-cut and microwave sandwiches/subs with no frying or grilling on site, ice cream shops and beverage bars as defined by NAICS 72213, mobile food vendors as defined by NAICS 722330;

2. CLASS 2. Limited-service restaurants (a.k.a. fast food facilities) as defined by NAICS 722211 and caterers as defined by NAICS 722320;

3. CLASS 3. Full-service restaurants as defined by NAICS 722110;

4. CLASS 4. Buffet and cafeteria facilities as defined by NAICS 72212; and

5. CLASS 5. Institutions (schools, hospitals, prisons and the like) as defined by NAICS 722310 but not to exclude self-run operations.

GREASE (BROWN). Fats, oils and grease that is discharged to the grease control equipment, or is from kitchen or food prep wastewater.

GREASE (YELLOW). Fats, oils and grease that has not been in contact or contaminated from other sources (water, wastewater, solid waste and the like) and can be recycled.

GREASE CONTROL EQUIPMENT (GCE). A device for separating and retaining wastewater FOG prior to wastewater exiting the FSE and entering the City Utilities Board sewer system. The GCE is so constructed as to separate and trap or hold fats, oils and grease substances from entering the City Utilities Board sewer system. Devices include grease interceptors, grease traps or other devices approved by the Director.

GREASE INTERCEPTOR. Grease control equipment identified as a large tank, usually 1,000 gallon to 2,000 gallon capacity with proper inlet and outlet Ts, that provides FOG control for a FSE. GREASE INTERCEPTORS will be located outside the FSE, unless a variance request has been granted.

GREASE TRAP. Grease control equipment identified as an “under the sink” trap, a small container with baffles, or a floor trap. For a FSE approved to install a GREASE TRAP, the minimum size requirement is the equivalent of a 20-gallon per minute/40 pound capacity trap. All GREASE TRAPS will have flow control restrictor and a vent pipe.

GREASE RECYCLE CONTAINER. Container used for the storage of yellow grease.

NAICS. North American Industry Classification System. The website is found at: (http://www.census.gov/epcd/www/naics.html).

TEE or T (INFLUENT AND EFFLUENT). A T-shaped pipe extending from the ground surface below grade into the grease interceptor to a depth allowing recovery (discharge) of the water layer located under the layer of FOG. Influent and effluent T’s are recommended to be made of PVC or equivalent material, and extend to within 12 to 15 inches of the bottom of the interceptor.

WATER (BLACK). Wastewater containing human waste, from sanitary fixtures such as toilets and urinals.

WATER (GRAY). Refers to all other wastewater other than black water as defined in this section.

(C) General requirements.

(1) All existing food service establishments (FSEs) are required to have grease control equipment (GCE) installed, maintained and operating properly.

(2) All FSEs will be required to maintain records of cleaning and maintenance of GCE. GCE maintenance records include, at a minimum, the date of cleaning/maintenance, company or person conducting the cleaning/maintenance, amount or volume of grease wastewater removed. A grease waste hauler completed manifest will meet this requirement.

(3) GCE maintenance records will be available at the FSE premises so they can be provided to City Utilities Board personnel or its representative, and/or the Health Department. The FSE shall maintain GCE maintenance records for three years.

(4) No FSE will discharge oil and grease in concentrations that exceed the city instantaneous grab limit for oil and grease.

(5) All FSEs are required to dispose of yellow grease in an approved container, where contents will not be discharged to any storm water grate, drain or conveyance. Yellow grease, or any oils or grease, poured or discharged into the FSE sewer lines or City Utilities Board sewer system is a violation of this chapter.

(6) New food service establishment, upgrading of existing food service establishment or change of ownership of existing food service establishment requirement: any new FSE, upgrading of an existing FSE or change of ownership of existing FSE will be required to install and maintain a grease interceptor. Food service establishments in one of these categories must submit a FOG plan to City Utilities Board for approval. The FOG plan includes identification of all cooking and food preparation equipment (i.e., fryers, grills, woks and the like); the number and size of dishwashers, sinks, floor drains and other plumbing fixtures; type of FSE classification; type of food to be served; and plans for the grease interceptor dimensions and location. The City Utilities Board will review the FOG plan, grease interceptor sizing and approve, or make changes as necessary to aid in the protection of a FOG discharge from the FSE.

(7) Existing food service establishments will be phased in to compliance through their FSE permit and a compliance schedule. The compliance schedule will be determined by the FSE ERG as defined in § 51.34.

(8) Variance to grease interceptor installation: at the discretion of the Director, some FSEs may receive a variance from the required installation of a grease interceptor.

(9) Grease control equipment sizing.

(a) Minimum acceptable size of grease control equipment for each FSE classification will be as follows:

1. Class 1: Deli, ice cream shops, beverage bars, mobile food vendors - 20 gallons per minute/40 pound grease trap (at discretion of the Superintendent);

2. Class 2: Limited-service restaurants/caterers - 1,000 gallon grease interceptor;

3. Class 3: Full-service restaurants - 1,000 gallon grease interceptor;

4. Class 4: Buffet and cafeteria facilities - 1,500 gallon grease interceptor; and

5. Class 5: Institutions (schools, hospitals, prisons and the like) - 2,000 gallon grease interceptor.

(b) 1. To calculate the appropriate size GCE, the following formula will be used: Fixture Units (total) x Facility type multiplier x 36 (retention time) = Size of Interceptor (gals.).

2. Should the size of the interceptor calculate to 499 gallons or less with the formula above: Size of interceptor (gals.) x 0.75 (max. cap. of sink) = Flow (gpm) x hours (work day) = Acceptable Flow rate with retention time.

(10) Grease control equipment specifications.

(a) Grease control equipment must remove fats, oils and grease at or below enforcement action in accordance with the City Utilities Food Service Establishment Enforcement Response Guide.

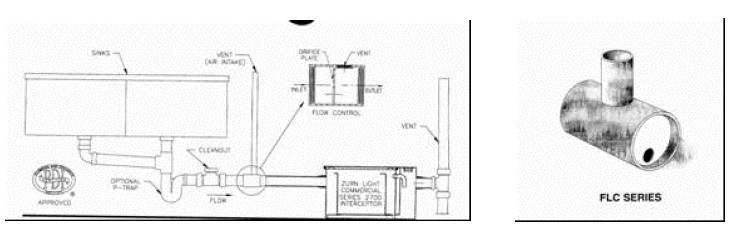

(b) Grease traps must have the Plumbing Drainage Institute certification. The minimum acceptable size is rated at 20 gpm/40 pounds. All grease traps will be installed as per manufacturer specifications, which includes the flow restrictor and venting prior to the discharge entering the grease trap.

(11) Grease interceptors.

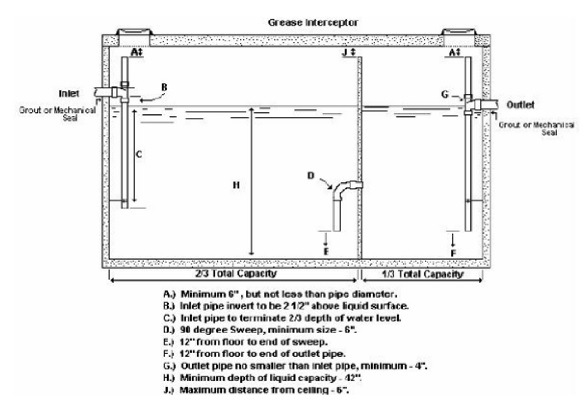

(a) Piping design.

1. The inlet and outlet piping shall have two-way cleanout tees installed;

2. The inlet piping shall enter the receiving chamber two and one-half inches above the invert of the outlet piping;

3. On the inlet pipe, inside the receiving chamber, a sanitary tee of the same size pipe in the vertical position with the top unplugged shall be provided as a turndown. To provide air circulation and to prevent “air lock”, a pipe (nipple) installed in the top tee shall extend to a minimum of six inches clearance from the interceptor ceiling, but not less that the inlet pipe diameter. A pipe installed in the bottom of the tee shall extend to a point of two-thirds the depth of the tank. See illustration;

4. The outlet piping shall be no smaller than the inlet piping, but in no case smaller than four inches ID;

5. The outlet piping shall extend to 12 inches above the floor of the interceptor and shall be made of a non-collapsible material; and

6. The outlet piping shall contain a tee installed vertically with a pipe (nipple) installed in the top of the tee to extend to a minimum of six-inch clearance from the interceptor ceiling, but not less that the pipe diameter, with the top open. See illustration.

(b) Baffles.

1. The grease interceptor shall have a non-flexing (i.e., concrete, steel and the like) baffle the full width of the interceptor, sealed to the walls and the floor, and extend from the floor to within six inches of the ceiling. The baffle shall have an inverted 90 degree sweep fitting at least equal in diameter size to the inlet piping, but in no case less than six inches ID. The bottom of the sweep shall be placed in the vertical position in the inlet compartment 12 inches above the floor. The sweep shall rise to the horizontal portion, which shall extend through the baffle into the outlet compartment. The baffle wall shall be sealed to the sweep. See illustration.

2. The inlet compartment shall be two-thirds of the total liquid capacity with the outlet compartment at one-third liquid capacity of the interceptor.

(c) Access openings (manholes).

1. Access to grease interceptors shall be provided by a minimum of one manhole per interceptor division (baffle chamber) and of 24-inch minimum dimensions terminating one inch above finished grade with cast iron frame and cover. An eight-inch thick concrete pad extending a minimum of 12 inches beyond the outside dimension of the manhole frame shall be provided. One manhole shall be located above the inlet tee hatch and the other manhole shall be located above the outlet tee hatch. A minimum of 24 inches of clear opening above each manhole access shall be maintained to facilitate maintenance, cleaning, pumping and inspections.

2. Access openings shall be mechanically sealed and gas-tight to contain odors and bacteria and to exclude vermin and ground water, in a manner that permits regular re-uses.

3. The manholes are to be accessible for inspection by the Department.

(D) Additional requirements.

(1) Water-tight. Precast concrete grease interceptors shall be constructed to be water-tight. A static water test shall be conducted by the installer and timed so as to permit verification through visual inspection by regulatory agent. The water test shall consist of plugging the outlet (and the inlet if necessary) and filling the tank(s) with water to the tank top a minimum of 24 hours before the inspection. The tank shall not lose water during this test period. Certification by the plumbing contractor shall be supplied to the City Utilities prior to final approval of grease control equipment.

(2) Location. Grease control equipment shall be located so as to be readily accessible for cleaning, maintenance and inspections. They should be located close to the fixture(s) discharging the greasy wastestream.

(3) Responsibility. Removal of the grease from the wastewater routed to a public or private sanitary system is the responsibility of the user/owner.

(4) Construction material. Grease interceptors shall be constructed of sound durable materials, not subject to excessive corrosion or decay, and shall be water- and gas-tight. Each interceptor shall be structurally designed to withstand any anticipated load to be placed on the interceptor (i.e., vehicular traffic in parking or driving areas).

(E) Grease interceptor cleaning/maintenance requirements.

(1) Grease interceptor minimum size will be 1,000 gallon capacity, and maximum size will be 2,500 gallon capacity. If the FSE needs additional capacity, then grease interceptors will be installed in series.

(2) Partial pump of interceptor contents or on-site pump and treatment of interceptor contents will not be allowed due to reintroduction of fats, oils and grease to the interceptor and pursuant to the C.F.R. § 403.5(b)(8), which states “Specific prohibitions. In addition, the following pollutants shall not be introduced into a POTW: Any trucked or hauled pollutants, except at discharge points designated by the POTW”.

(3) Grease interceptors must be pumped-in-full when the total accumulations of surface FOG (including floating solids) and settled solids reaches 25% of the grease interceptor’s overall liquid depth. This criterion is referred to as the “25% Rule”. At no time, shall the cleaning frequency exceed 90 days unless approved City Utilities Board. Approval will be granted on a case by case situation with submittal by the FSE documenting proof of proposed frequency. Some existing FSEs in Class 2 through 5 will need to consider monthly pumping to meet this requirement.

(4) Grease interceptor effluent-T will be inspected during cleaning and maintenance and the condition noted by the grease waste hauler’s company or individual conducting the maintenance. Effluent-T’s that are loose, defective or not attached must be repaired or replaced immediately.

(5) Grease interceptors must have access manholes over the influent-T and effluent-T for inspection and ease of cleaning/maintenance. Access manholes will be provided for all separate compartments of interceptors for complete cleaning (i.e., interceptor with two main baffles or three compartments will have access manholes at each compartment).

(F) Grease trap cleaning/maintenance requirements.

(1) All grease traps will have flow control restrictor and vented. Failure to have the flow restrictor and venting will be considered a violation.

(2) Grease trap minimum size requirement is a 20 gallon per minute/40 pound capacity trap.

(3) Grease traps will be cleaned of complete fats, oils and grease and food solids at a minimum of every two weeks, unless less cleaning frequency is authorized by City Utilities. If the FOG and food solids content of the grease trap is greater than 50%, then the grease trap must be cleaned every week, or as frequently as needed to prevent 50% of capacity being taken from FOG and food solids.

(4) Grease trap waste should be sealed or placed in a container to prevent leachate from leaking, and then disposed.

(5) Grease trap waste should not be mixed with yellow grease in the grease recycle container.

(G) Food service establishment FOG permits and inspections. The City Utilities Board may issue FOG permits to food service establishments to control FOG discharges to the city sewer system, prevent obstruction and interference to the POTW, and prevent sanitary sewer overflows. The City Utilities Board may establish food service establishment FOG permit classifications, or issue general FOG permits to each food service establishment. Also, the City Utilities Board, or their authorized representative, will conduct inspections of food service establishments for grease control equipment installation and maintenance, types of food served and preparation of food, impact to the city sewer system, and review of best management practices. The City Utilities Board, or its authorized representative, has the right to enter the food service establishments’ premises to determine impacts to the city sewer system. The City Utilities Board will conduct any additional monitoring of the food service establishment to determine compliance with the FOG management policy.

(H) Fees. The City Utilities Board may charge FOG permit, inspection or monitoring fees to the food service establishments to get reimbursement for the FOG program costs.

(I) “Additives” prohibition for use as grease management and control.

(1) Additives include but are not limited to products that contain solvents, emulsifiers, surfactants, caustics, acids, enzymes and bacteria.

(2) At no time will additives be used just prior to under the sink or floor grease traps.

(3) The use of additives is prohibited with the following exceptions.

(a) Additives may be used to clean the FSE drain lines but only in such quantities that it will not cause fats, oils and grease to be discharged from the grease control equipment to the sewer system, or cause temporary breakdown of FOG that will later re-congeal in the downstream sewer system.

(b) If the product used can be proven to contain 100% bacteria, with no other additives. Approval of the use of the product must come from the Director and FSE must submit a full disclosure MSDS and certified sample results from the manufacturer of the product.

(4) The use of approved additives will in no way be considered as a substitution to the maintenance procedures required herein.

(J) Enforcement action. Enforcement action against the FSE includes, but is not limited to, failure to clean or pump grease control equipment, failure to maintain grease control equipment including inspection and installation of properly functioning effluent-T and baffles, failure to install grease control equipment, failure to control FOG discharge from the FSE, contributing to a sewer line blockage or obstruction, contributing to a sanitary sewer overflow, and use of additives in such quantities so that FOG is pushed downstream of the FSE.

(K) Fats, oils and grease blockage in downstream manhole from FSE. If FSE inspections and field investigations by City Utilities, or its authorized representative, determine that any fats, oils and grease interference or blockage in the sewer system, a sewage pumping station, or the wastewater treatment plant is caused by a particular food service establishment, then that food service establishment shall reimburse the City Utilities Board for all labor, equipment, supplies and disposal costs incurred by the City Utilities Board to clean the interference or blockage. The charges will be added to the FSEs water/wastewater bill. Failure to reimburse the City Utilities Board will result in termination of water service.

(L) FSE failure to maintain GCE after notification or NOV due date. If a FSE fails to pump, clean or maintain their GCE after a non-compliance notification or notice of violation due date, the City Utilities Board may chose to pump/clean the GCE to prevent additional FOG problems downstream. The FSE will be charged for the cost of pumping and maintaining the FSE’s GCE at a rate of one and one- half times the cost to the City Utilities Board. Mechanical failure of the GCE will be considered a violation of the City Sewer Use Ordinance which pertains to the construction and maintenance of pretreatment facilities and subject to penalties of up to $10,000/day for each day in violation.

(M) Penalties. Penalties will be issued as per the City Utilities Board FSE Enforcement Response Guide.

(Ord. 699, passed 10-26-2009)