(a) Grease, oil and sand interceptors shall be provided when, in the opinion of the Manager of the wastewater treatment plant and/or the Engineer and/or the Plumbing Inspector, they are necessary for the proper handling of liquid wastes containing grease in excessive amounts, or any flammable wastes, sand and other harmful ingredients, except that such interceptors shall not be required for private living quarters or dwelling units. All interceptors shall be of a type and capacity approved by the City and shall be located as to be readily and easily accessible for cleaning and inspection.

(b) Where installed, all grease, oil and sand interceptors shall be maintained by the owner, at their expense, in continuously efficient operation at all times.

(c) Fats, Oils, and Grease Control.

(1) The purpose of the Fats, Oils, and Grease Fog (FOG) Control Regulations are:

A. To prevent the introduction of FOG into the Public Sewer that will interfere with its operation;

B. To prevent the introduction of FOG into the Public Sewer, the Publicly Owned Treatment Works, and, if inadequately treated, into receiving waters.;

C. To prevent sanitary sewer overflow (SSO) that can contaminate the soil, local water bodies and any property that the sewerage comes into contact with;

D. To prevent an obstruction in the sanitary sewer causing a back-up of sewage into homes and businesses;

E. To reduce maintenance and repair costs, which are borne by all the users of the sanitary sewer system.

(2) Applicability.

A. This regulation shall apply to all non-domestic users of the Public Sewer.

B. Grease interceptors shall not be required for residential users.

C. This regulation shall apply to both new and existing facilities generating fats, oils, or greases as a result of food manufacturing, processing, preparation, or food service. These facilities are referred to as "Food Service Establishments" in this regulation, and are required to install, use, and maintain appropriate grease interceptors as required in subsection (c)(3) of this regulation. These facilities include, but are not limited to, restaurants, food manufacturers, food processors, hospitals, hotels and motels, prisons, nursing homes, and any other facility preparing, serving, or otherwise making any foodstuff available for consumption.

D. FOG Generators are responsible for maintaining grease interceptors in continuous proper working condition, by removing the oil and grease buildup in the interceptor at sufficient intervals to ensure compliance with the City of Massillon Sewer Rules and Regulations. Further, FOG generators are responsible for inspecting, repairing, replacing, or installing apparatus and equipment as necessary to ensure proper operations and function of grease interceptors and compliance with discharge limitations at all times.

(3) Grease Interceptors Required.

A. New Facilities. Food processing or food service facilities which are newly proposed or constructed, or existing facilities which will be expanded or renovated to include a food service facility, where such a facility did not previously exist, shall be required to design, install, operate and maintain a grease interceptor in accordance with these regulations. Grease interceptors shall be installed and inspected prior to use.

B. Existing Facilities. Existing facilities undergoing any of the following shall be required to design, install, operate and maintain a grease interceptor in accordance with these regulations, when the existing grease trap does not comply with these regulations.

1. Interior remodeling to accommodate expansion or operational modification;

2. Changes of ownership or occupancy;

3. Major changes in their menu and when an existing facility experiences difficulty achieving compliance with maintenance and/or wastewater discharge limitations.

(4) Location and Sizing Requirements:

A. The location of grease traps shall be outside the building and provide easy access for cleaning and inspection. Sizing methods described herein are intended to assist in determining grease trap/interceptor sizes that will afford the City's sanitary sewer system a minimum degree of protection against grease and other obstructing materials. In approving a customer's plumbing or grease interceptor design, the City does not accept liability for the failure of a system to adequately treat wastewater to achieve effluent quality requirements stated. It is the responsibility of the generator and/or contractors to insure the appropriate level of treatment necessary for compliance with wastewater regulations.

B. Minimum acceptable grease interceptor sizing shall be accomplished as follows:

1. Sizing according to formulas found in subsection (c)(4)C. below.

2. Where sizing formulas result in determination of a grease interceptor less than 750 gallons in capacity, this minimum size is required wherever possible. The maximum required grease interceptor size shall be 3,000 gallons.

3. In instances where it is physically impossible to install an outside grease trap, a letter must be submitted to the Massillon City Building Department stating the reasons it cannot be installed and then a general review by the Building Department will follow to verify the validity of the claim.

4. In the circumstance of "single service kitchens" with no food preparation (heat/serve only), that use only disposable paper and plastic service utensils, and do not have a high temperature dishwasher, a hydro-mechanical grease trap with draw-off valve may be used. Additionally, when an exterior grease interceptor is deemed physically impossible as stated in subsection (c)(4)B.3., a hydromechanical grease trap with draw-off valve may be used. The trap must meet PDI-G 101 specifications. In these instances, the grease trap is to be installed in an area separate from the food handling area and the trap must be readily accessible for cleaning and maintenance. (See subsection (c)(4)C. below.) Grease trap will be sized as per subsection (c)(4)C.

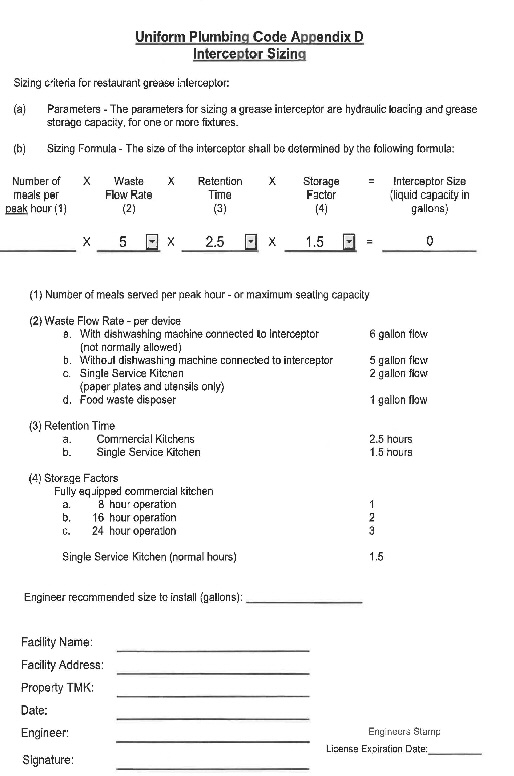

C. Grease Interceptor sizing formulas.

1. It is the responsibility of the generator and his/her contractors to ensure that the wastewater discharged from their facility is in compliance with the City's discharge limitations. For the purpose of plan review, a general assessment of grease trap/interceptor design and size will be performed using the following formula: (Source: Appendix D of the Uniform Plumbing Code, Grease Interceptor Sizing Worksheet.)

(# of meals/per peak hour) x (waste flow RATE) x (retention) x (storage) = size

(1) (2) (3) (4)

Factors:

(1) # of meals served at peak operating hour (Seating Capacity)x(Peak Factor):

a. Peak Factor for Fast Food Restaurant is ...... 1.33

b. Peak Factor for all other food service types is ... 1.00

(2) Waste Flow Rate:

a. with dishwasher .............................................. 6 gallon flow

b. without dishwasher .......................................... 5 gallon flow

c. single service kitchen ...................................... 2 gallon flow

d. food waste disposer .......................................... 1 gallon flow

(3) Retention times:

a. commercial kitchen waste/dishwasher ......................... 2.5 hours

b. single service kitchen/single serving ............................ 1.5 hours

(4) Storage factors:

a. fully equipped commercial kitchen ...... 8 hr. operation= 1

b. fully equipped commercial kitchen .... 16 hr. operation = 2

c. fully equipped commercial kitchen ..... 24 hr. operation= 3

d. single service kitchen ... ........................................ = 1.5

D. Example.

A seventy-five (75) seat restaurant is open from 4:00 pm. until 12:00 am.

It has a dishwasher and a fully equipped commercial kitchen on a normal street.

(Number of meals)x(waste flow)x(retention)x(storage)= size requirement (75)(1)] x (6 gallons) x (2.5 hours) x (1) = 1125 gals.

E. Hydro-mechanical Grease Trap Sizing

1. Determine the volume of all fixtures being drained (cubic inches).

2. Convert cubic inches into gallons.

3. Determine actual drainage load seventy-five percent (75%) of total content).

4. Determine flow rate for two (2) minute drainage period.

5. Flow rate= actual drainage load -:- drainage period.

TABLE 1 | |

Capacity of Grease Traps | |

Total Flow Through Rating (GPM) | Grease Retention Capacity (Pounds) |

4 | 8 |

6 | 12 |

7 | 14 |

9 | 18 |

10 | 20 |

12 | 24 |

14 | 28 |

15 | 30 |

18 | 36 |

20 | 40 |

25 | 50 |

35 | 70 |

50 | 100 |

- Proper sizing to be approved by Massillon Building Department. | |

(5) Construction/Installation.

A. All permitting, construction, and inspection activities must be completed in accordance with the Ohio Plumbing Code. Additionally, the following specifications must be incorporated into grease interceptor design.

1. Commercial dishwashers must be properly designed, located, installed, and operated to prevent the introduction of detergents and/or high-water temperatures capable of melting grease or causing grease to pass through the interceptor. Grease interceptors are to be installed at a minimum distance of ten (10) feet from sinks and dishwashers to allow for adequate cooling of the wastewater. Water temperatures must be less than 140 degrees prior to entering grease interceptor.

2. All grease bearing waste streams should be routed through an appropriate grease interceptor, including: three-compartment sinks, pot/pan sinks, soup kettles, dishwashers, mop sinks and floor drains. Drains that receive "clear waste" only, such as from ice machines, condensate from coils and drink station may be plumbed to the sanitary system without passing through the grease interceptor.

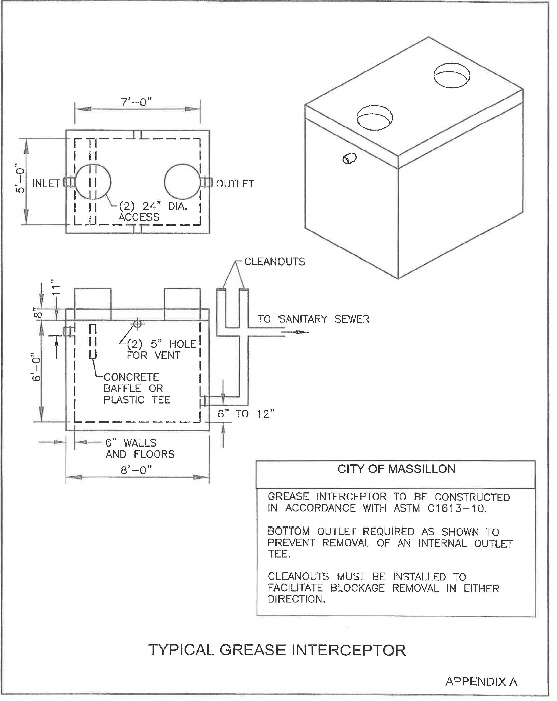

3. All exterior grease interceptors will be equipped with a minimum of one twenty (20) inch diameter access hole, and additional access holes at the inlet and outlet sides of the tank for ease of cleaning. All interceptors shall be vented. Concrete interceptors must meet the latest version of ASTM C1613-10, Standard Specification for Precast Concrete Grease Interceptor Tanks. High Density Polyethylene (HDPE) Interceptors must meet the latest version of ASTM F2649 (latest revision) Standard Specification for Corrugated High-Density Polyethylene (HDPE) Grease Interceptor Tanks. Interceptors constructed of other materials shall meet the applicable ASTM standard. The pipe exiting the grease interceptor shall be installed six (6) to twelve (12) inches from the bottom of the tank, rather than near the top of the tank, to eliminate the risk of tee/baffle removal or breakage which would render the interceptor ineffective. The pipe shall be installed to maintain the correct water level within the tank and be equipped with clean-outs to allow for line maintenance in either direction of flow. (See appendix A.)

(6) Cleaning and Maintenance.

A. It is the responsibility of the Generator (owner) to ensure compliance with the City of Massillon Sewer discharge limitations. Grease interceptors must be operated and maintained in accordance with the manufacturer's recommendations and in accordance with these regulations, unless specified in writing and approved by the Wastewater Treatment plant manager, or the Engineer, or their authorized agents.

1. Grease interceptors shall be maintained in an efficient operating condition at all times.

2, Each grease interceptor when cleaned shall be fully evacuated by removing all solids, wastewater, and grease. Grease shall be removed from the interceptor walls, the inlet pipe, and the outlet pipe by pressure washing, physical scraping or other acceptable means.

3. No interceptor shall create a nuisance during operation or cleaning.

4. Self-Cleaning; Hydro-mechanical Grease interceptors only.

a. Grease interceptor self-cleaning operators may remove grease from their own grease hydro-mechanical grease interceptors. The following conditions shall apply:

i. The grease interceptor is no more than 100 GPM size.

ii. Proper on-site material disposal methods are implemented (e.g. absorb liquid into solid form and dispose into trash);

iii. The disposal methods do not create a nuisance and are done in accordance with law;

iv. Grease waste is placed in a leak proof, sealable container(s) located on the premises and in an area for the transporter to pump- out; and

v. Detailed records on these activities are maintained.

b. Grease interceptor self-cleaning operators must maintain a self-cleaning plan that meets cleaning schedule outlined in this regulation. The plan shall include the following information:

i. Business name and street address;

ii. Grease interceptor operator name, title, and phone number;

iii. Description of maintenance frequency, method of disposal, method of cleaning, and size (in gallons) of the grease interceptor; and

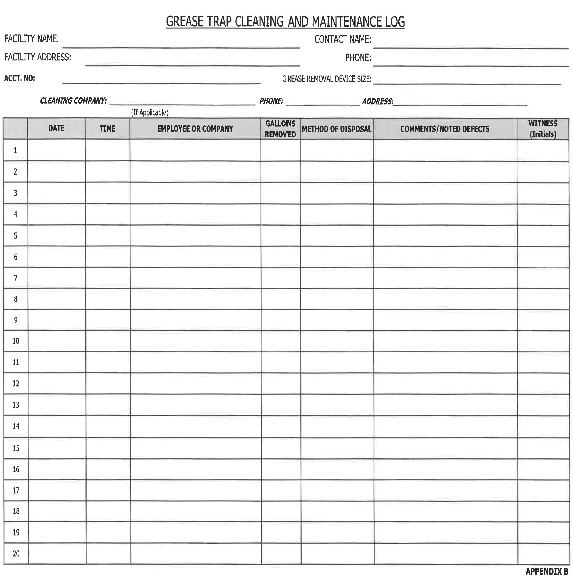

c. A maintenance log (Appendix B) shall be kept by self-cleaning operators that indicates, at a minimum, the following information:

i. Date the grease trap/interceptor was serviced;

ii. Name of the person or company servicing the grease trap/interceptor;

iii. Waste disposal method used;

iv. Gallons of grease removed and disposed of;

v. Waste oil added to grease interceptor waste; and

vi. Signature of the operator after each cleaning that certifies that all grease was removed, disposed of properly, grease trap/interceptor was thoroughly cleaned, and that all parts were replaced and in operable condition.

d. Violations incurred by grease interceptors' self-cleaners will be subject to enforcement action and may be required to contract with a grease removal service.

(7) Cleaning Schedules.

A. Grease interceptors shall be cleaned as often as necessary to ensure that sediment and floating materials do not accumulate to impair the efficiency of the grease interceptor; to ensure the discharge is in compliance with local discharge limits; and to ensure no visible grease is observed in discharge.

B. Grease interceptors shall be completely evacuated a minimum of every sixty (60) days, or more frequently when:

1. Twenty-five percent (25%) or more of the wetted height of the grease trap or grease interceptor, as measured from the bottom of the device to the invert of the outlet pipe, contains floating materials, sediment, oils or greases; or

2. The discharge exceeds BOD, COD, TSS, FOG, pH, or other pollutant levels established by the City; or

3. If there is a history of non-compliance.

C. Any person who owns or operates a grease interceptor may submit to the Wastewater Treatment plant manager or Engineer a request in writing for an exception to the sixty (60) day cleaning frequency of their grease interceptor. The Wastewater Treatment plant manager or Engineer may grant an extension for required cleaning frequency on a case-by-case basis when:

1. The grease interceptor owner/operator has demonstrated the specific interceptor will produce an effluent, based on defensible analytical results, in consistent compliance with established local discharge limits such as BOD, TSS, FOG, or other parameters as determined by the Wastewater Treatment plant manager or Engineer.

2. Less than twenty-five percent (25%) of the wetted height of the grease interceptor, as measured from the bottom of the device to the invert of the outlet pipe, contains floating materials, sediment, oils or greases.

3. In no case shall a grease interceptor be fully evacuated, cleaned, and inspected at an interval greater than once every one-hundred twenty (120) days.

(8) Manifest Requirements.

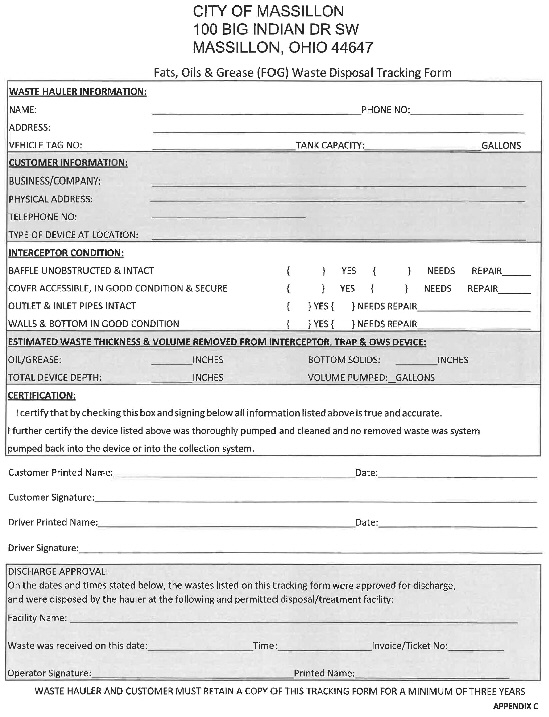

A. Each pump-out of a grease interceptor must be accompanied by a manifest to be used for record keeping purposes (Appendix C).

B. Persons who generate, collect and transport grease waste shall maintain a record of each individual collection and deposit. Such records shall be in the form of a manifest. The manifest shall include:

1. Name, address, telephone of transporter;

2. Name, signature, address, and phone number of the person who generated the waste and the date collected;

3. Type and amount(s) of waste collected or transported;

4. Name and signature(s) of responsible person(s) collecting, transporting, and depositing the waste;

5. Date and place where the waste was deposited;

6. Identification (permit or site registration number, location, and operator) of the facility where the waste was deposited;

7. Name and signature of facility on-site representative acknowledging receipt of the waste and the amount of waste received;

8. The volume of the grease waste received; and

9. A consecutive numerical tracking number to assist transporters, waste generators, and regulating authorities in tracking the volume of grease transported.

C. Manifests shall be divided into four (4) parts and records shall be maintained as follows:

1. One part of the manifest shall have the generator and transporter information completed and given to the generator at the time of waste pickup.

2. The remaining four (4) parts of the manifest shall have all required information completely filled out and signed by the appropriate party before distribution of the manifest.

3. One part of the manifest shall go to the receiving facility.

4. One part shall go to the transporter, who shall retain a copy of all manifests showing the collection and disposition of waste.

5. One copy of the manifest shall be returned by the transporter to the person who generated the wastes within fifteen (15) days after the waste is received at the disposal or processing facility.

6. Copies of manifests returned to the waste generator shall be retained for five (5) years and be readily available for review by the Wastewater Treatment plant manager, or the Engineer, or their authorized agents.

D. All grease interceptor waste shall be properly disposed of at a facility in accordance with federal, state, or local regulations.

(9) Compliance Testing.

A. All testing designed to satisfy the criteria set forth in these regulations shall be scientifically sound and statistically valid. All tests to determine oil and grease, TSS, BOD, COD, pH, and other pollutant levels shall use appropriate tests which have been approved by the Environmental Protection Agency which are defined in Title 40, Code of Federal Regulations, Part 136. Testing shall be open to inspection by the Wastewater Treatment plant manager, or the Engineer, or their authorized agents and shall meet the City's approval.

(10) Best Management Practices and Employee Training.

A. BMP's. All Food Service Establishments shall implement the following Best Management Practices (BMPs) to minimize the discharge of FOG to the sewer system.

1. "Dry wipe" pots, pans, dishware and work areas before washing to remove grease.

2. Properly dispose of food waste and solids in enclosed plastic bags prior to disposal in trash bins or containers to prevent leaking and odors.

3. Use of absorption products to clean under fryer baskets and other locations where grease may be spilled or dripped.

4. Properly dispose of grease or oils from cooking equipment into a grease receptacle such as a barrel or drum without spilling.

5. Kitchen exhaust filters cleaned as frequently as necessary to be maintained in good operating condition. The wastewater generated from cleaning the exhaust filter must be disposed properly through a grease interceptor or grease trap.

B. Kitchen signage. Best management and waste minimization practices shall be posted conspicuously in the food preparation and dishwashing areas at all times.

C. Training. All employees of a food processing or food service facility shall be trained by the ownership/ management at least annually, on BM P's. Records of training sessions and any accompanying educational materials shall be retained by the waste generator (owner) for five (5) years and be readily available for review by the Wastewater Treatment plant manager, or the Engineer, or their authorized agents.

(11) Prohibited Practices.

A. No person shall introduce, or cause, permit, or allow the introduction of any surfactant, solvent or emulsifier into a grease interceptor. Surfactants, solvents, and emulsifiers are materials which allow the grease to pass from the grease interceptor into the collection system, and include but are not limited to enzymes, soap, diesel, kerosene, terpene, gasoline and other solvents. Additionally, hazardous wastes, such as acids, strong cleaners, pesticides, herbicides, or paint shall not be introduced into a grease interceptor.

B. No user may intentionally or unintentionally allow the direct or indirect discharge of any fats, oils, or greases of animal or vegetable origin into the Public Sewer in such amounts as to cause interference with the collection and treatment system, or as to cause pollutants to pass through the treatment works into the environment.

(12) Compliance Monitoring.

A. Right of Entry. The Wastewater Treatment plant manager, or the Engineer, or their authorized agents shall have the right to enter the premises of any user or potential user to determine whether the user is complying with all requirements of this chapter and any wastewater discharge permit or order issued hereunder. Users shall allow the Wastewater Treatment plant manager, or the Engineer, or their authorized agents ready access to all parts of the premises for the purposes of inspection, sampling, records examination and copying, and the performance of any additional duties.

1. Where a user has security measures in force which require proper identification and clearance before entry into its premises, the user shall make necessary arrangements with its security so that, upon presentation of suitable identification, the Wastewater Treatment plant manager, or the Engineer, or their authorized agents will be permitted to enter without delay for the purposes of performing specific responsibilities.

2. The Wastewater Treatment plant manager, or the Engineer, or their authorized agents shall have the right to set up on the user's property or require installation of devices as are necessary to conduct sampling and/or metering of the user's operations. The Wastewater Treatment plant manager, or the Engineer, or their authorized agents may also require the user to install monitoring equipment as necessary, such as FOG sensing and alarm devices complying with PDI G102. The installation of all such devices shall be at the owner's expense. The facility's monitoring equipment shall be maintained at all times in a safe and proper operating condition by the user at its own expense.

3. Any temporary or permanent obstruction to safe and easy access to the facility to be inspected and/or sampled shall be promptly removed by the owner at the written or verbal request of the Wastewater Treatment plant manager, or the Engineer, or their authorized agents and shall not be replaced. The costs of clearing such access shall be borne by the owner.

4. Unreasonable delays in allowing the Wastewater Treatment plant manager, or the Engineer, or their authorized agents access to the user's premises shall be a violation of this regulation.

B. Search Warrants. If the Wastewater Treatment plant manager, or the Engineer, or their authorized agents or his authorized agent has been refused access to a building, structure, or property, or any part thereof, and is able to demonstrate probable cause to believe that there may be a violation of this chapter, then the Wastewater Treatment plant manager, or the Engineer, or their authorized agents may seek issuance of a search warrant.

(13) Enforcement.

A. Massillon City Council finds that specific enforcement provisions must be adopted to govern discharges to the City's Public Sewer system by Food Service Establishments to ensure that the City's sewer facilities are protected and are able to operate with the highest degree of efficiency, and to protect the public health and environment.

B. The Wastewater Treatment plant manager, or the Engineer, or their authorized agents will determine noncompliance with the provisions of this FOG Control Regulation through visual inspections, records review, sampling, and/or monitoring of Food Service Establishments.

1. If, through visual inspection, the Food Service Establishment is found to be out of compliance or cannot provide the documentation requested by the Wastewater Treatment plant manager, or the Engineer, or their authorized agents, the establishment will be given thirty (30) days to become compliant or to provide the requested documentation before it will be considered a violation.

C. When a Food Service Establishment is found to be in noncompliance with one or more of the provisions of this regulation, a written Notice of Violation (NOV) will be issued to the Food Service Establishment with a specified time frame to come into compliance. If the Food Service Establishment fails to properly address the causes and/or sources of the noncompliance, then the Wastewater Treatment plant manager, or the Engineer, or their authorized agents may pursue additional enforcement options, including but not limited to:

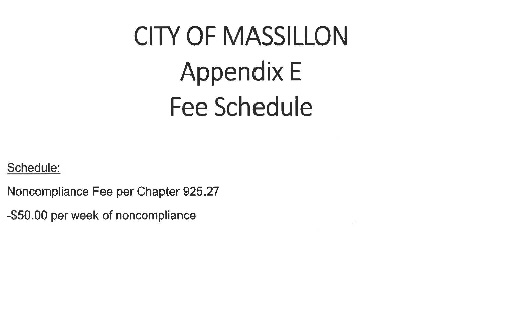

1. Assess noncompliance fees to the Food Service Establishment. A Food Service Establishment determined to be in noncompliance with the provisions specified in this regulation shall pay a noncompliance fee. The purpose of the noncompliance fee is to compensate the City for costs of additional inspection and follow-up, clean-up, sampling, monitoring, laboratory analysis, and administrative processing incurred as a result of the noncompliance (See appendix E).

2. Compliance Schedule. The Wastewater Treatment Plant Manager, or the Engineer, or their authorized agents may enter into a Compliance Schedule with a Food Service Establishment. A Compliance Schedule may contain terms and conditions including but not limited to requirements for installation of a grease control device and devices to facilitate sampling, immediate and regular pumping and maintenance of grease control device, submittal of drawings or reports, submittal of waste hauling records, implementation of best management and waste minimization practices, payment of fees, or other provisions to ensure compliance with this regulation. The Wastewater Treatment plant manager, or the Engineer, or their authorized agents shall not enter into a Compliance Schedule until such time as all amounts owed by the Food Service Establishment to the City, including user fees, noncompliance sampling fees, and/or other amounts due are paid in full, or an agreement for deferred payment secured by collateral or a third party, is approved by the Wastewater Treatment plant manager, or the Engineer, or their authorized agents.

3. Injunctive Relief. When the Wastewater Treatment plant manager, or the Engineer, or their authorized agents finds that a user has violated or continues to violate any provision of this regulation, or order issued hereunder, or any other pretreatment standard or requirement, the City may petition the Court of Common Pleas for the issuance of a temporary or permanent injunction, as appropriate, which restrains or compels the user to comply with the performance standards stated in this regulation, or order imposed under this regulation. The City may also seek such other action as is appropriate for legal and/or equitable relief, including a requirement for the user to conduct environmental remediation. A petition for injunctive relief shall not be a bar against or a prerequisite for taking any other action against a user.

4. Terminate sewer service. After other means have failed to gain compliance, the City may terminate the user's sewer service. All costs for physical termination shall be paid by the owner or operator of the Food Service Establishment or Designee, as well as costs for reinstating service.

(Ord. 106-2023. Passed 11-28-23.)

APPENDIX A

(Ord. 106-2023. Passed 11-28-23.)

APPENDIX B

(Ord. 106-2023. Passed 11-28-23.)

APPENDIX C

(Ord. 106-2023. Passed 11-28-23.)

APPENDIX D

(Ord. 106-2023. Passed 11-28-23.)

APPENDIX E

(Ord. 106-2023. Passed 11-28-23.)